When it comes to optimizing vehicle performance and ensuring longevity, understanding the dynamics of your car’s transmission system is key. Among these, the transmission cooler plays a crucial role, specifically designed to reduce excessive heat generated by the transmission during operation.

Its effectiveness, however, hinges heavily on something called the ‘transmission cooler flow direction’. This might seem like a complex term, but it simply refers to the path taken by the transmission fluid as it circulates within the cooling system.

The optimal direction of transmission cooler flow is from the transmission to the cooler and then back to the transmission. This allows the transmission fluid to:

- Absorb heat from the transmission

- Get cooled in the cooler

- Return to the transmission to repeat the process

This guide will discuss the intricacies of transmission cooler flow direction. It will explain how it works, why it’s important, and provide a comprehensive understanding to aid in vehicle maintenance.

The Mechanics of Vehicle Transmission

Vehicle transmission transfers the power generated by the engine to the wheels, thereby causing the vehicle to move. It involves the precise shifting of gears to match the optimal power and speed conditions. Modern vehicles can have either manual or automatic transmissions, each with its own set of mechanics.

How Heat Impacts Transmission

Excessive heat can be detrimental to the vehicle’s transmission system. It can lead to the degradation of the transmission fluid, which is crucial for the lubrication and cooling of the transmission. This can cause parts to wear out faster, leading to decreased vehicle performance and potential breakdowns.

Importance of Transmission Fluid

Transmission fluid lubricates the moving parts to reduce friction and wear. Second, it acts as a coolant to absorb and disperse the heat generated. Lastly, it also helps transfer the hydraulic pressure necessary for the gear-shifting process.

The quality and condition of the transmission fluid directly impact the performance and longevity of the transmission system. Over time, the fluid can degrade and lose its effectiveness, leading to increased friction, higher temperatures, and reduced performance. Regular checks and changes of transmission fluid can help maintain optimal transmission performance and longevity.

Transmission Coolers

A transmission cooler helps control the temperature of the transmission fluid within the transmission system. Acting as a radiator of sorts for the transmission, its main job is to cool the transmission fluid that absorbs heat from the transmission system.

By maintaining the fluid at an optimal temperature, a transmission cooler contributes to overall vehicle performance and longevity.

How It Works

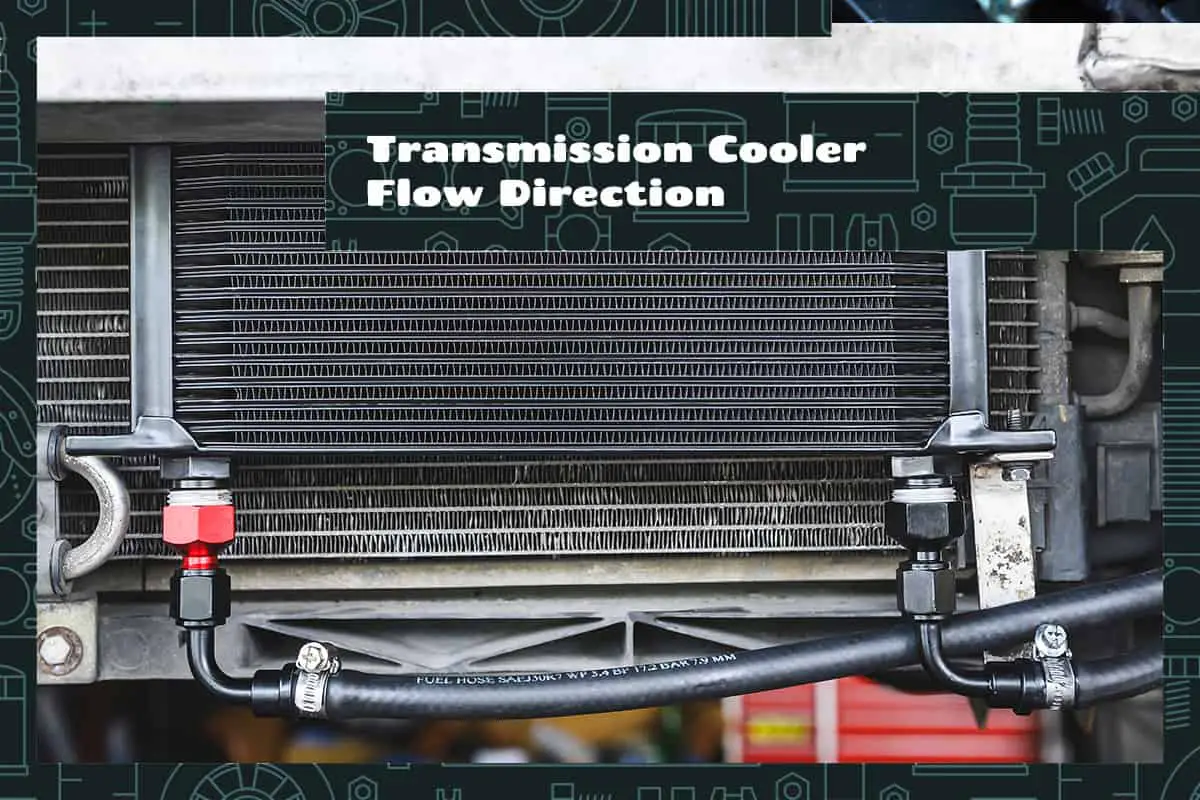

A transmission cooler works by receiving the hot transmission fluid from the transmission system, cooling it, and then sending it back to the transmission system. The cooler is usually located at the front of the vehicle, where it can receive airflow, aiding in the cooling process.

The hot transmission fluid enters the cooler and is passed either through the tube or plates, depending on the type of cooler. The surrounding fins help dissipate the heat from the fluid into the ambient air. Once cooled, the fluid exits the cooler and returns to the transmission system to absorb more heat, repeating the cycle.

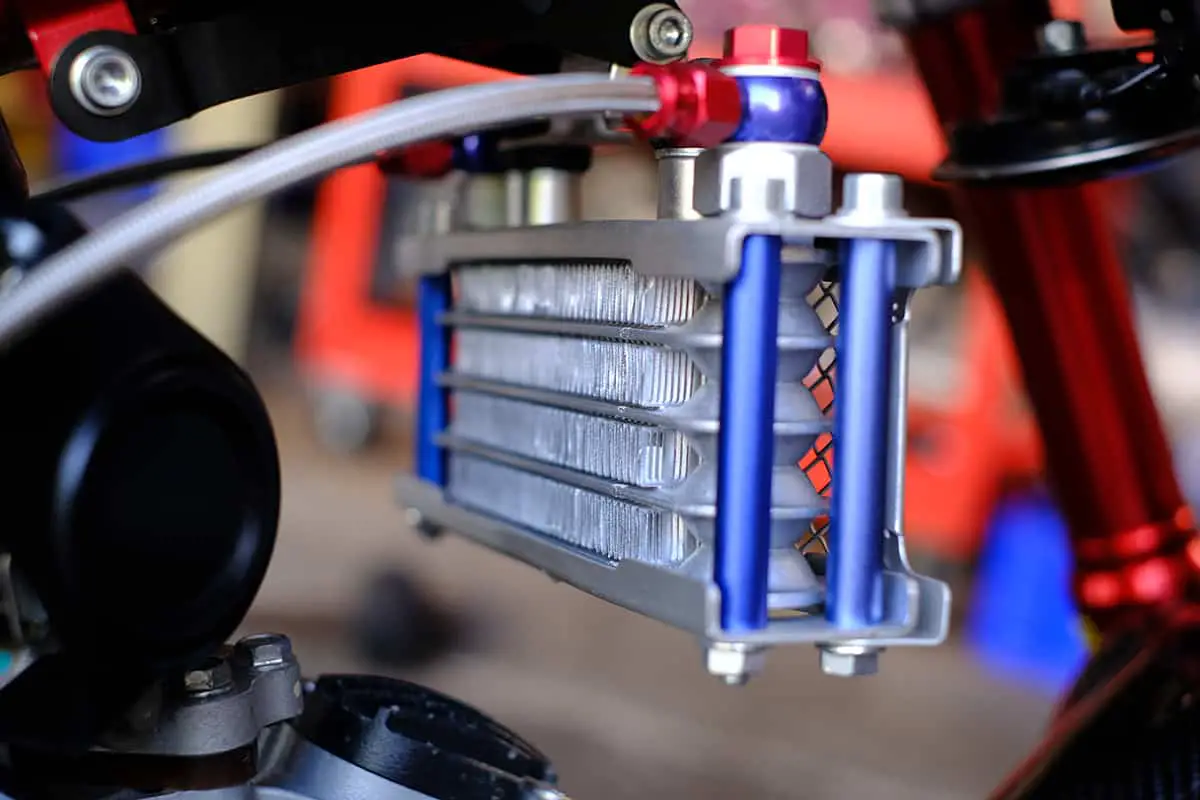

Types of Transmission Coolers

There are mainly three types of transmission coolers: tube-and-fin, plate-and-fin, and stacked plate coolers.

- Tube-and-Fin Coolers: This is the simplest and often the most economical type. It consists of a tube carrying the hot transmission fluid, surrounded by fins to disperse the heat. While cost-effective, these may not be the most efficient for demanding conditions.

- Plate-and-Fin Coolers: More efficient than the tube-and-fin design, these coolers use a series of plates instead of a tube. The fluid moves through the plates, and the heat is dissipated through the fins. This design allows for quicker cooling, making it suitable for moderate to heavy-duty applications.

- Stacked Plate Coolers: This design offers the highest efficiency. The transmission fluid is passed through multiple plates stacked together, providing a larger surface area for heat dissipation. Despite being more expensive, these coolers are ideal for heavy-duty applications due to their excellent cooling capabilities.

Transmission Cooler Flow Direction Explained

Transmission cooler flow direction refers to the path that the transmission fluid follows as it moves from the transmission system to the transmission cooler and back again. For optimal function and cooling efficiency, the fluid should flow from the transmission through the cooler and then back into the transmission. The direction is crucial as it ensures that the transmission fluid absorbs heat from the transmission, gets cooled in the cooler, and then returns to the transmission to repeat the process.

The correct transmission cooler flow direction ensures that the transmission fluid can effectively cool down before it reenters the transmission. This sequence helps maintain the optimal operation of the transmission by preventing overheating.

Overheating can cause the transmission fluid to degrade, which compromises its ability to lubricate the moving parts effectively. This can increase wear and tear, leading to decreased performance and even potential transmission failure.

Proper flow direction also helps prolong the lifespan of the transmission fluid. By ensuring the fluid is adequately cooled before reentering the transmission, it stays in better condition for longer, reducing the need for frequent changes.

Signs of Incorrect Transmission Cooler Flow Direction

Incorrect transmission cooler flow direction can lead to a range of issues, from decreased vehicle performance to more severe transmission problems. Some signs that may indicate incorrect transmission cooler flow direction include:

- Transmission Overheating: This is often the first sign. If the transmission fluid is not adequately cooled, the transmission system can overheat, leading to decreased performance and potentially severe damage.

- Frequent Transmission Fluid Changes: If the transmission fluid is consistently running too hot, it can degrade more quickly, necessitating more frequent changes.

- Decreased Vehicle Performance: Over time, an incorrect flow direction can lead to decreased overall vehicle performance. This can manifest as reduced fuel efficiency, slower acceleration, or trouble shifting gears.

Maintaining Optimal Transmission Cooler Performance

1. Regular Inspection and Maintenance

The first step in maintaining optimal transmission cooler performance is regular inspection and maintenance. This includes checking the cooler lines for any signs of wear and tear, leaks, or blockages that could affect the flow of transmission fluid.

Regularly checking and changing the transmission fluid is also crucial to ensure it can effectively absorb heat from the transmission and be cooled in the cooler.

2. Correct Installation

Proper installation of the transmission cooler is vital to ensure optimal flow direction and performance. The cooler should ideally be located at the front of the vehicle, where it can receive maximum airflow for cooling. It should also be installed in a way that the transmission fluid flows from the transmission to the cooler and then back into the transmission.

3. Choosing the Right Transmission Cooler

Choosing the right transmission cooler for your vehicle and its usage is also important. While tube-and-fin coolers might be suitable for most normal driving conditions, if you frequently drive in heavy traffic, tow heavy loads, or live in a hotter climate, a plate-and-fin or stacked plate cooler may be more appropriate.

4. Transmission Cooler Line Inspection

The cooler lines that transport the transmission fluid from the transmission to the cooler and back are also crucial for maintaining optimal performance.

Any leaks, blockages, or incorrect connections can affect the transmission cooler flow direction, leading to ineffective cooling and potential transmission issues. Regular inspection and prompt repair or replacement of damaged lines can help maintain correct flow direction and efficient cooling.

5. Transmission Fluid Quality

Maintaining the quality of the transmission fluid is crucial for effective cooling. Regular checks can ensure the fluid is in good condition and capable of absorbing and transferring heat effectively. If the fluid appears dark or smells burnt, it may be time for a change.

6. Monitoring Transmission Temperature

Regular monitoring of the transmission temperature can provide useful insights into the performance of the transmission cooler. A consistent, unusually high temperature could indicate issues with the transmission cooler flow direction, cooler line, or the cooler itself.