Timing belts synchronize the rotation of the crankshaft and camshafts. When working properly, they ensure that your engine’s valves open and close at the correct times during each cylinder’s intake and exhaust strokes. But like any other part of your car, timing belts wear out over time and can cause significant engine damage if not addressed promptly.

The symptoms of a bad timing belt are as follows:

- Ticking noise coming from the engine

- Engine misfires or runs poorly

- Difficulty in starting the car

- Loss of oil pressure

- Smoke from the engine compartment

This guide will cover the symptoms of a failing timing belt in more detail and learn how to replace a bad timing belt.

The Vital Role of Timing Belts in Vehicles

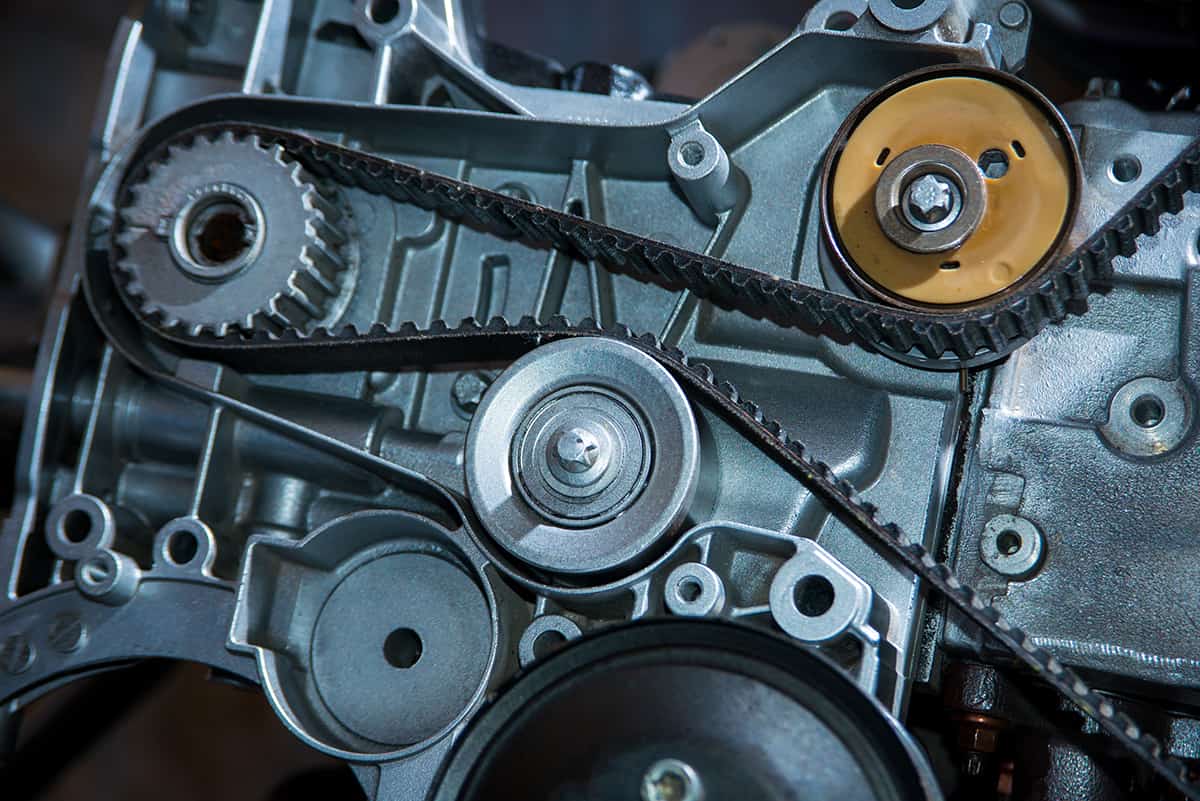

A timing belt, sometimes referred to as a cambelt, is a toothed belt made of high-quality rubber. This critical engine component connects the crankshaft to the camshaft(s), making sure they run in unison. The crankshaft controls the engine’s pistons, while the camshaft opens and closes the valves. The timing belt ensures these processes occur at the right time to prevent the pistons and valves from colliding.

When the engine is running, the timing belt rotates the engine’s camshaft and crankshaft in synchronized motion. This movement opens and closes the engine’s valves in time with the motion of the pistons. As a rule of thumb, the intake valves open during the intake stroke to allow the air-fuel mixture into the cylinders. After the mixture combusts, the exhaust valves open to release the combustion gases. Without a timing belt to manage these tasks, the engine would fail.

Symptoms of a Failing Timing Belt

A timing belt doesn’t often give visual signs of wear until it’s too late, so you should look for the following symptoms that indicate it may be time for a replacement.

1. Ticking Noise from the Engine

The most distinctive symptom of a failing timing belt is ticking or clicking noises from the engine. This sound is usually an indication that your timing belt is wearing thin or not appropriately tensioned.

The timing belt is made from rubber and reinforced with high-strength fibers. This rubber can wear, or the fibers can break, causing the belt to become loose and creating a ticking sound as the belt and gears make contact.

2. Engine Misfires or Runs Poorly

A timing belt in good condition ensures synchronization between the crankshaft and the camshaft. This synchronization is vital for the engine’s pistons and valves to operate smoothly. However, when the timing belt is failing, it can slip or even break, causing this synchronization to fail. When this happens, it may result in a misfire, where the combustion process is out of order.

3. Difficulty in Starting the Car

If the timing belt is broken, the engine’s crankshaft will not turn, preventing the engine from starting. In this case, you may hear the starter motor engage when you turn the key, but the engine itself will not start.

4. Loss of Oil Pressure

The timing belt is located near many of your vehicle’s essential oil channels. If the timing belt wears out or breaks, it can lead to engine oil leakage. This leakage can result in a severe loss of oil pressure, leading to poor engine performance and potential engine failure.

5. Smoke from the Engine Compartment

If the timing belt fails, the engine will run hot due to misfires and poor combustion. This excess heat can cause various engine components to overheat, producing smoke or even causing a fire in severe cases.

Replacing Bad Timing Belts

If you’ve identified a bad timing belt in your car, you only have one option: replacement. Let’s see how this process is done.

Confirming a Bad Timing Belt

Confirming a bad timing belt is done by checking for signs of wear or damage. These signs can include visible cracks, a loosened belt, or stripped teeth. It’s crucial to diagnose a bad timing belt correctly to avoid the risk of catastrophic engine damage.

Timing Belt Replacement

Replacing a timing belt is a labor-intensive task that requires specific knowledge and tools. The replacement process involves removing the old belt and inspecting other parts, such as tensioners and pulleys, for wear and tear. Once these components are confirmed to be in good shape, a new belt is installed.

Step-by-Step Guide for DIY Replacement

Timing belt replacement is generally a task for professional mechanics due to the precision required and the risk of damaging the engine. However, a DIY replacement is possible for car owners with advanced automotive knowledge and the right tools.

Here’s what you’ll need:

- Set of wrenches and sockets

- Screwdrivers

- Torque wrench

- Timing light

- New timing belt (and possibly new tensioners, pulleys, and a water pump)

Here is a basic overview of the replacement process. Timing belt replacement procedures can vary greatly depending on the make and model of your vehicle. Refer to your vehicle’s service manual for detailed instructions.

- Preparation: Start by parking your vehicle on a flat surface. Disconnect the battery and allow the engine to cool if it was recently running.

- Access the Timing Belt: Remove the components blocking access to the timing belt, which can include the alternator, AC compressor, power steering pump, and engine mount.

- Mark the Current Timing Settings: Before removing the old belt, mark the position of the camshaft and crankshaft pulleys relative to the engine block. This step ensures that you can install the new belt in the correct timing position.

- Remove the Old Timing Belt: Loosen the tensioner and remove the old timing belt. Inspect the tensioner and pulleys for wear and replace if necessary.

- Install the New Timing Belt: Install the new belt, ensuring that the belt and pulleys align with your markings from Step 3. Apply the appropriate tension to the belt according to the manufacturer’s specifications.

- Reassemble the Engine: Reinstall all the components removed in Step 2. Reconnect the battery.

- Test the Installation: Start the engine and let it idle while observing the belt. The belt should run smoothly, and there should be no abnormal sounds. Use a timing light to confirm that the engine’s timing is set correctly.

FAQs

1. What causes the timing belt to malfunction?

The most common is normal wear and tear, as the belt is made of rubber and continuously exposed to engine heat. Over time, this leads to the belt becoming brittle and cracking.

Another cause is improper tension; a belt that’s too tight or loose can cause premature failure.

Other factors include oil or coolant leaks that can degrade the belt, a misaligned or worn pulley causing uneven wear, or the failure of related components such as the tensioner or water pump.

2. How long can you drive with a bad timing belt?

Driving with a bad-timing belt is not recommended. The timing synchronizes the crankshaft and camshaft rotation, ensuring your engine’s valves open and close at the correct times. If the timing belt fails while driving, it can cause significant engine damage, including bent valves, cylinder head or camshaft damage, and piston and cylinder wall damage.

The exact duration you can drive with a bad timing belt is unpredictable and depends on the extent of the belt’s wear or damage. But the risk is high and immediate replacement is the safest course of action.

3. How much does it cost to replace a timing belt?

As a general range, you can expect the cost of parts and labor for a timing belt replacement to fall somewhere between $300 and $700. If you opt for a timing belt kit, which includes the belt along with other components like tensioners, pulleys, and sometimes the water pump, the cost could rise to around $700 to $1000.