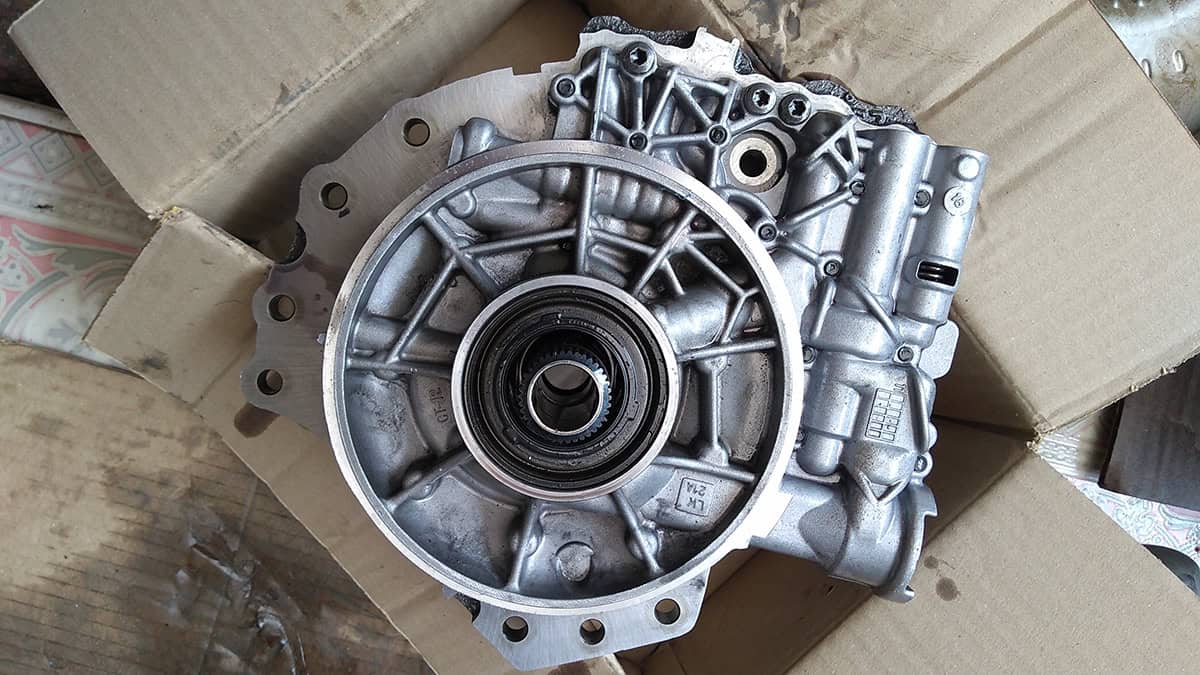

A transmission pump is the heart of your vehicle’s transmission system, pumping transmission fluid to keep everything running smoothly. However, things can go pretty badly over time, and that can lead to serious issues for your car.

A bad transmission pump can give you some clear signs, such as a delayed response from your vehicle, strange noises coming from the transmission, difficulties with shifting gears, overheating of the transmission, and leaks of transmission fluid.

In this article, we will delve deeper into the world of transmission pumps. We’ll explore why they’re so important, what causes them to fail, and how to fix them.

What is a Transmission Pump?

A transmission pump is a mechanical device that is driven by the engine. When the engine starts, the pump begins to operate, circulating the transmission fluid around the system. There are three main types of transmission pumps used in vehicles: gear pumps, and vane pumps.

1. Gear pumps

Gear pumps are the most common type of pump used in automotive transmissions. They consist of two gears: one is connected to the engine (the drive gear), and the other is not (the driven gear).

When the engine runs, it rotates the drive gear, which in turn moves the driven gear. The space between the gears and the pump housing is filled with transmission fluid. As the gears rotate, they push the fluid out of the pump and into the transmission system.

2. Vane pumps

Vane pumps have a rotor with slots in which vanes or blades can slide. This rotor is positioned off-center in a circular cavity. When the engine drives the rotor, the centrifugal force pushes the vanes out against the cavity’s walls. As the rotor spins, the vanes trap pockets of transmission fluid and move it from the inlet to the outlet of the pump.

3. Rotor pumps

The rotor pump is named for its design, which consists of two or more rotating gears. These gears can be either external or internal. In an external gear pump, two identical gears rotating against each other, with the inner side of each gear in continuous contact.

As these gears rotate, they create a vacuum on the inlet side, which draws in transmission fluid. This fluid is then trapped in the spaces between the gears and the pump casing and carried around to the outlet side, where it is pushed out of the pump and into the transmission.

Signs and Symptoms of a Bad Transmission Pump

Your car also shows signs when its transmission pump isn’t working right. These signs act as an early warning system to help you address the issue before it turns into a major problem, such as a failing TCM.

1. Delayed vehicle response

When you step on the gas, your car should immediately start to move forward. If it takes a moment or two for your vehicle to get going, this could be a sign that your transmission pump is failing. That delay is because the pump is not circulating enough transmission fluid to help change the gears smoothly.

2. Unusual noise from the transmission

It could sound like a whining or buzzing noise. This happens because the pump may be struggling to circulate the transmission fluid, or it could be due to the wear and tear of the pump components.

3. Issues with gear shifting

If there’s a problem with the pump, you might have trouble shifting gears or feel a jolt when the gears change. In automatic transmissions, you could experience what’s known as “hard shifting,” where the car jerks or lurches during gear changes. For manual transmissions, it might become difficult to change gears.

4. Transmission overheating

If your transmission pump isn’t working properly, it can cause your transmission to overheat. This can lead to further damage if not addressed quickly. Your vehicle’s temperature gauge can help you monitor this.

5. Transmission fluid leaks

A leak of red fluid (which is what transmission fluid usually looks like) could be a sign of a bad transmission pump. This is because a failing pump could cause seals and gaskets to break down, resulting in low transmission levels and leaks.

Causes of Transmission Pump Failure

Knowing the causes can help you prevent these issues from happening in the first place, or at least catch them early when they do happen.

1. Normal wear and tear

Everything wears out eventually, and the transmission pump is no exception. Over time, the components of the pump can wear down. This can cause the pump to perform less efficiently and eventually fail. Regular maintenance and checks can help catch wear and tear before it leads to a complete pump failure.

2. Incorrect installation

If the transmission pump isn’t installed correctly, it can lead to problems. This could happen if someone without the right skills or tools tries to install the pump. A poorly installed pump might not circulate the transmission fluid properly, leading to inadequate lubrication and potential overheating.

3. Inadequate fluid levels

The transmission pump needs enough fluid to work properly. If there’s not enough fluid, or if the fluid is old and dirty, the pump has to work harder and may eventually fail. It’s crucial to check your transmission fluid regularly and replace it as recommended by your vehicle’s manufacturer.

4. Contaminated transmission fluid

The transmission fluid can become contaminated with dirt, metal shavings, or other debris. This can happen if the transmission is not properly maintained or if the vehicle is frequently driven in harsh conditions. Contaminated fluid can damage the pump and other components of the transmission.

Repairing and Replacing a Bad Transmission Pump

When your transmission pump starts acting up, you may need to repair or replace it. But remember, working on a transmission pump is a complex task that usually needs a professional mechanic. Here’s an overview of what’s involved.

Diagnosing the problem

First, it’s important to confirm that the transmission pump is the issue. This can be tricky because many transmission problems have similar symptoms. A mechanic can use specialized tools and experience to determine if the pump is at fault.

Repairing the pump

Sometimes, the transmission pump can be repaired. This might involve replacing worn-out components, fixing leaks, or cleaning out contaminated fluid. However, repair is not always possible or cost-effective.

Replacing the Pump

If the pump can’t be repaired, or if it would be too expensive compared to replacing it, the next step is to install a new pump. Here’s a simplified version of what that process might look like:

- Disconnect the Battery: This is a safety step to prevent any accidental sparks or electrical shorts.

- Lift the vehicle: The mechanic will use a lift or jack stands to get access to the underside of the vehicle.

- Remove the transmission: This is a big job. The mechanic will need to disconnect various components and then carefully lower the transmission.

- Remove the old pump: The mechanic will open up the transmission to get to the pump. They’ll then disconnect it and remove it from the transmission.

- Install the new pump: The new pump will be carefully installed in place of the old one.

- Reassemble the transmission and vehicle: After the new pump is in, the mechanic will put everything back together.

- Fill with new transmission fluid: Fresh transmission fluid will be added. It’s crucial to use the right type and amount of fluid.

- Test the vehicle: The mechanic will test the vehicle to make sure the new pump is working correctly and that there are no leaks.

Again, repairing or replacing a transmission pump is heavy-duty work and should be done only by an expert. So, if you lack the expertise to take out the old transmission and fix it up or swap it out, leave it to the pros.