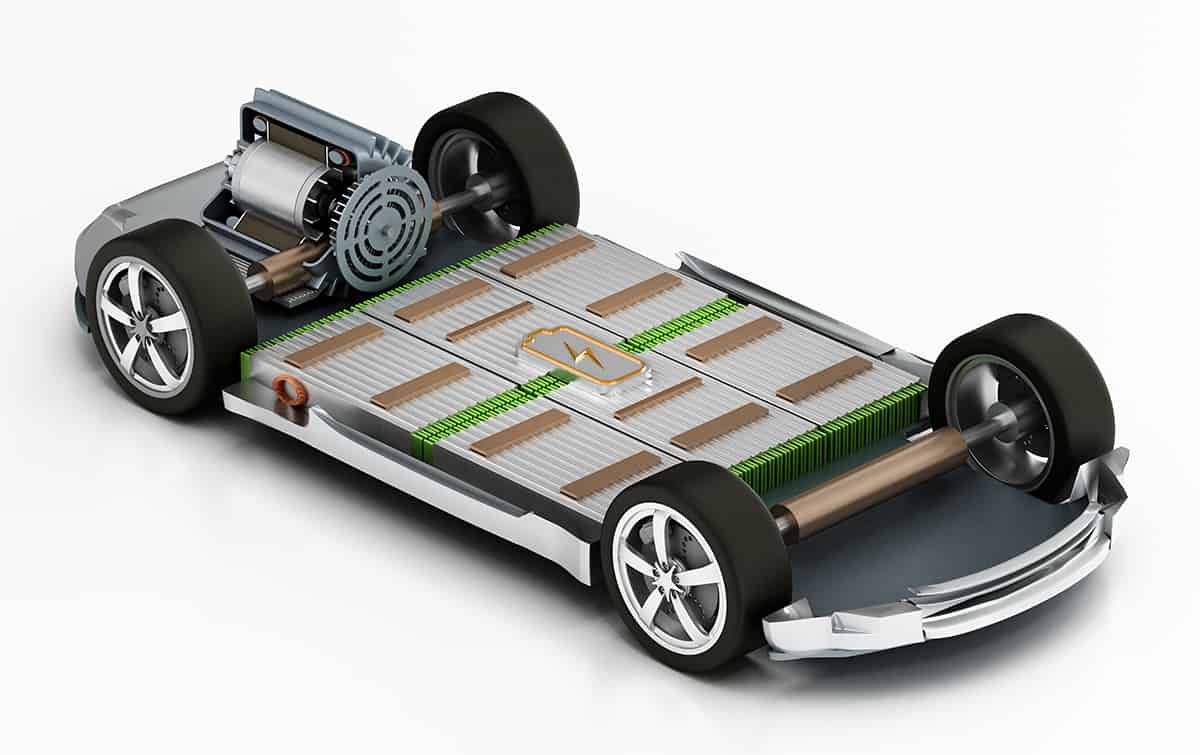

The electric vehicle (EV) revolution is reshaping the automotive industry, with more people shifting from traditional gasoline cars to electric cars. A key component of an electric car is its battery, which directly impacts its weight, efficiency, and overall performance.

The average weight of an EV battery is around 1,000 pounds, though some models may sport 1-ton batteries. In general, a heavier EV battery will produce greater power and store more energy for longer trips per charge.

In this article, we will delve into the importance of electric car battery weight, factors affecting it, and how it influences driving range and efficiency. We will also explore the latest innovations in battery technology, environmental impact, and maintenance and replacement considerations.

What is an Electric Car Battery?

An electric car battery is a rechargeable energy storage system that powers the electric motor in an electric vehicle. There are several types of electric car batteries, including lithium-ion, nickel-metal hydride, and solid-state batteries. These batteries vary in terms of energy density, weight, charging speed, and lifespan.

Compared to traditional lead-acid batteries found in gasoline cars, electric car batteries generally have higher energy density, better efficiency, and longer lifespans. However, they can be more expensive and require advanced cooling systems to maintain optimal performance.

Factors that Affect Electric Car Battery Weight

As mentioned earlier, an EV battery will weigh between 1,000 and 2,000 pounds. Here, we’ll go over the causes of this wide weight disparity.

1. Battery chemistry

Different chemistries, such as lithium-ion or nickel-metal hydride, have varying energy densities and weights. Lithium-ion batteries typically offer higher energy density and are lighter than other chemistries.

2. Battery size

The physical dimensions of a battery contribute to its weight. Larger batteries tend to weigh more but can store more energy.

3. Battery capacity

Higher capacity batteries can store more energy, increasing driving range but also adding weight to the vehicle.

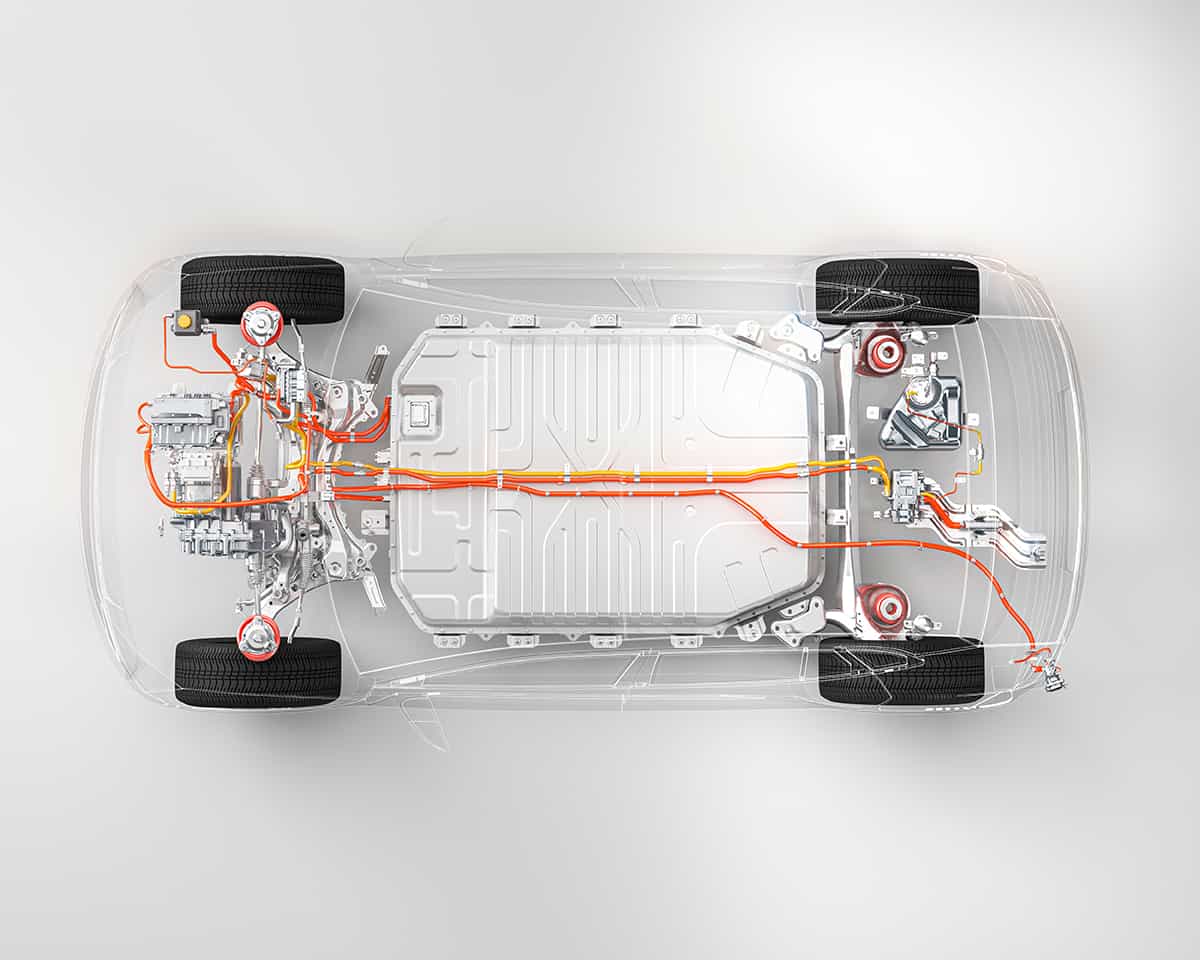

4. Cooling systems

Effective cooling systems are essential for battery longevity and performance. These systems can add weight to the battery pack, depending on their complexity.

5. Safety features

Protective measures, such as fire-resistant materials and impact-resistant casings, contribute to battery weight but are vital for ensuring safety during operation.

6. Other components

Additional components, like battery management systems and electrical wiring, can also influence battery weight, although their contribution is usually smaller compared to the factors mentioned above.

How Electric Car Battery Weight Affects Efficiency

A heavier battery increases the overall weight of the car, requiring more energy to be expended during acceleration and maintaining speed. This increased energy consumption reduces the vehicle’s overall efficiency.

Conversely, a lighter battery contributes to a lighter vehicle, which requires less energy for movement, thereby improving efficiency.

How Electric Car Battery Weight Affects Driving Range

A heavier battery usually has a higher capacity, allowing it to store more energy and potentially offer a longer driving range. However, the increased weight also means that the vehicle requires more energy to move, which can offset the potential benefits of the larger battery capacity.

On the other hand, a lighter battery results in a lighter vehicle, which requires less energy to operate. This can improve the vehicle’s energy efficiency but may come at the expense of a reduced driving range due to the lower battery capacity.

Latest Innovations in Electric Car Battery Technology

The electric vehicle industry is continually working to improve aspects like battery technology and charging infrastructure

The latest innovations in electric car battery technology include the development of solid-state batteries, which promise to make electric cars more convenient and affordable. These batteries can utilize a wide range of chemistries and are considered a leading candidate for future EVs. Researchers are also exploring how materials for solid-state batteries could impact large-scale manufacturing, with the goal of designing better batteries for electric vehicles.

Some companies have found ways to use silicon to store electricity inside batteries, replacing the graphite prevalent in current designs. Silicon can hold much more energy per pound than graphite, potentially leading to significant improvements in battery performance.

NAWA Technologies has designed and patented an Ultra Fast Carbon Electrode, which utilizes a vertically-aligned carbon nanotube (VACNT) design, potentially revolutionizing the battery market.

Importance of Balancing Battery Weight and Performance

Balancing battery weight and performance is crucial for optimizing the efficiency, longevity, and overall functionality of a battery pack, particularly in applications such as electric vehicles.

Cell balancing helps achieve a higher state of charge (SoC) and ensures that all cells within a battery pack perform uniformly, which ultimately maximizes capacity and extends battery life. Proper cell balancing allows for better energy and power delivery, becoming increasingly important as the battery pack ages and differences between cells become more pronounced.

Environmental Impact of Electric Car Battery Weight

The environmental impact of electric car batteries is significant, particularly during the production process, which accounts for around 46% of an EV’s total carbon emissions. The manufacturing of electric car batteries can emit 74% of carbon dioxide, with the rate increasing when vehicles are running.

However, over the lifetime of an electric vehicle, the overall emissions are significantly lower than internal combustion engine vehicles, with fuel combustion being the primary contributor to emissions in traditional vehicles. Despite the initial environmental cost, electric vehicles ultimately provide a greener alternative to gasoline-powered cars.

Maintenance and Replacement of Electric Car Batteries

Here are a few things to keep in mind in order to get the most out of your EV battery.

- Avoid regularly fully charging and depleting the battery to prevent degradation of the battery pack.

- Follow the manufacturer’s recommended maintenance schedule for your specific electric vehicle.

- Be aware that electric vehicles require less maintenance overall compared to conventional cars due to fewer moving parts and no need for oil changes.

- Battery replacement costs can range from $4,000 to $18,000, depending on the vehicle and battery type.

- Most electric vehicles come with separate battery warranties that often last longer than the standard manufacturer warranty for the rest of the car.

- Battery costs have decreased significantly over the years, making replacements more affordable.

- There are 3 ways to charge electric car batteries: Level 1 (household-style outlet), Level 2 (220-volt charger), and Level 3 (480-volt DC charger for rapid charging).