The transmission is the heart of a car’s movement, converting engine power into movement on the road. Just like any heart, over time, it can wear out and require a bit of refurbishing. Many choose to rebuild their transmission instead of replacing it, as it can be cost-effective and give a vehicle a new lease on life.

Steps to Rebuild a Transmission:

- Drain the fluid

- Remove the transmission from the vehicle

- Disassemble the internal components

- Inspect and replace damaged parts

- Reassemble and refill with fresh fluid

- Reinstall into the vehicle

This guide will delve deeper into each of these steps. Please note that this is a general guide and you should consult a professional mechanic for further details.

Why and When to Rebuild a Transmission

The transmission, acting as the intermediary between the engine and the wheels, controls the power distribution and ensures smooth driving. Over time, wear and tear can reduce its efficiency, leading to performance issues and, in severe cases, complete failure. When this happens, you may have the option to rebuild the transmission.

Reasons to Rebuild

- Cost-Efficiency: Purchasing a brand-new transmission can be significantly more expensive than refurbishing an existing one. By replacing only the worn-out components, you can restore its functionality while saving money.

- Environmental Benefits: Rebuilding also promotes sustainability. Manufacturing a new transmission consumes resources and energy, leading to more waste and emissions. By choosing to rebuild, you’re recycling existing materials and reducing the demand for new ones.

- Vehicle Value: If you’re looking to sell your car, a well-functioning transmission can enhance its resale value. A rebuilt transmission assures potential buyers that the vehicle has been well-maintained and is worth the investment.

Signs It’s Time to Rebuild

- Slipping Gears: One of the most common symptoms is when the transmission unexpectedly changes gears. If you find your car shifting gears without any input or if it struggles to stay in gear, it could be a sign that the transmission bands are worn out.

- Unusual Noises: A transmission in distress can make a variety of sounds. If you hear grinding, whining, or clunking noises especially when in neutral, it’s a clear indication that something’s amiss.

- Delayed or Rough Shifting: If there’s a noticeable delay when shifting from park to drive or if the shifts are abrupt and jarring, it suggests that the transmission’s components are wearing out.

- Transmission Warning Light: Modern vehicles are equipped with sensors that monitor the health of the transmission. If the transmission warning light illuminates on your dashboard, it’s a signal that an issue needs addressing.

- Fluid Leaks and Discoloration: Transmission fluid should be a bright red color. If you notice dark or brownish fluid or spots beneath your vehicle, it’s a sign the fluid has aged or there’s a leak. Old fluid can lose its lubricating properties, causing more friction and wear within the transmission.

Tools and Materials Needed to Rebuild a Transmission

Having everything at hand ensures efficiency and accuracy in the process.

Hand Tools

For starters, an assortment of hand tools is essential.

- Wrenches will help you detach the transmission and work on its components.

- Pliers, both needle-nose and regular, aid in removing clips and retaining rings.

- Screwdrivers of varying sizes are needed for the various screws within the transmission.

- A rubber mallet or a soft hammer is also handy for nudging parts without causing damage.

Specialized Tools

While many tasks can be accomplished with basic tools, some processes require specialized equipment.

- A torque wrench tightens bolts to the exact specifications to prevent leaks.

- Transmission jack stands are specifically designed to support and maneuver the hefty weight of the transmission.

- Lastly, snap ring pliers help in dealing with the many snap rings you’ll encounter during disassembly and reassembly.

Materials and Consumables

When it comes to materials, new gaskets are at the top of the list. These ensure a leak-free seal when you close the transmission after rebuilding.

You’ll also need a transmission rebuild kit, tailored to your specific model, which typically includes various seals, o-rings, and friction clutches.

Fresh transmission fluid is necessary to replace the old fluid you drain.

Don’t forget cleaner and rags; a clean workspace and components are key to a successful rebuild.

Step-by-Step Guide to Rebuilding a Transmission

Again, this is just a general guideline of how rebuilding a transmission is done. If you don’t feel comfortable with this DIY approach, hiring a professional mechanic is your best option.

1. Preparation

Start by draining the transmission fluid into a suitable container. This reduces mess and keeps your working environment clean. Next, disconnect the vehicle’s battery for safety. With the battery and fluid out of the way, you’re ready to remove the transmission. Using your wrenches and, in some cases, a transmission jack, carefully detach it from the vehicle.

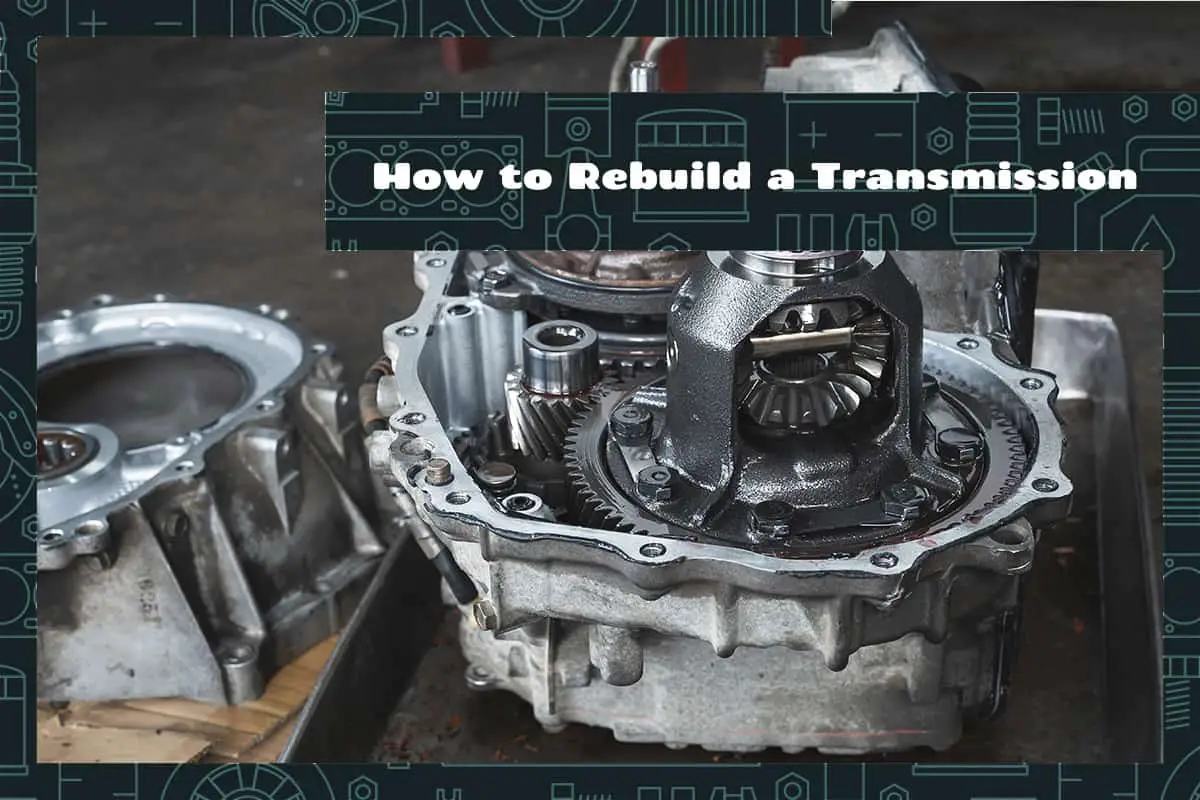

2. Disassembly

Lay out a clean workspace, preferably with a large table. As you take the transmission apart, it’s wise to organize parts in the order they’re removed. This makes reassembly more intuitive. Photographing each step can be a valuable reference for later. Begin by cleaning the exterior to prevent dirt from entering the internals.

Once cleaned, open the transmission case and lay out the internal components. Keep an eye out for small parts like springs and clips that can be easily misplaced.

3. Inspection

Examine each component for signs of wear or damage. Look for frayed clutches, worn seals, or damaged gears. The torque converter, a component that transfers power from the engine to the transmission, should also be checked. If it shows signs of wear or damage, consider refurbishing or replacing it.

4. Replacement and Repair

Some parts, like seals and gaskets, are typically replaced regardless of their condition. For components like gears, bearings, and synchros, you’ll have to weigh the cost and benefits of repair vs. replacement.

If you’ve purchased a transmission rebuild kit, many of these parts will be included. Also, pay special attention to the valve body, the brain of the transmission. Make sure it’s free from debris and that all passages are clear.

5. Reassembly

Start putting the transmission back together. Check that each component is returned to its rightful place. Utilize the torque wrench to make sure bolts are tightened to the manufacturer’s specifications. Once everything is in place, seal the transmission and be ready to fill it with fresh fluid.

6. Reinstallation into the Vehicle

Now that your transmission is rebuilt, it’s time to put it back in its home. Carefully position the transmission and connect it to the engine. Make sure all electronic components, linkages, and hoses are reconnected. Once securely in place, refill the transmission with the recommended fluid. Check for any leaks.

7. Testing

Start the vehicle and let it run to circulate the new fluid. Shift through all gears while stationary to check for smooth operation. Listen for any unusual noises. When you feel confident, take a short drive, paying attention to how the transmission responds.

8. Break-In Period

A rebuilt transmission needs some time to adjust. For the first few hundred miles, it’s best to drive gently, avoiding aggressive accelerations or decelerations. This allows the new parts to settle in and ensures longevity.

How Much Does Rebuilding a Transmission Cost?

The cost of rebuilding a transmission varies based on several factors:

- Type of Transmission: There are different types of transmissions—manual, automatic, and continuously variable transmissions (CVT). Typically, manual transmissions are less complex than automatic ones, so they’re slightly cheaper to rebuild. CVTs are a newer technology, and their costs can differ based on their unique components.

- The extent of Damage: The cost largely depends on the number of parts that need replacement. A transmission with minimal wear will cost less than one that’s extensively damaged.

- Parts: Opting for brand-new, OEM (Original Equipment Manufacturer) parts can be pricier than choosing aftermarket or refurbished parts. However, OEM parts typically come with a guarantee of compatibility and quality.

On average, for many common vehicles, the cost of rebuilding a transmission can range from $1,500 to $3,000. For luxury or specialized vehicles, or in cases where there’s extensive damage, the price can go upwards of $3,500.