Axles are central components of any vehicle that allow the wheels to rotate and providing stability. If you’ve looked at the undercarriage of your car, you may have noticed that it has 2 axles. But is this really the case? Mostly, yes.

Most standard cars have two axles. This means they possess a set of wheels in the front and another set in the back, each pair connected by its respective axle.

This guide will explore the mechanics of axles, their classifications, and common problems people face related to axles.

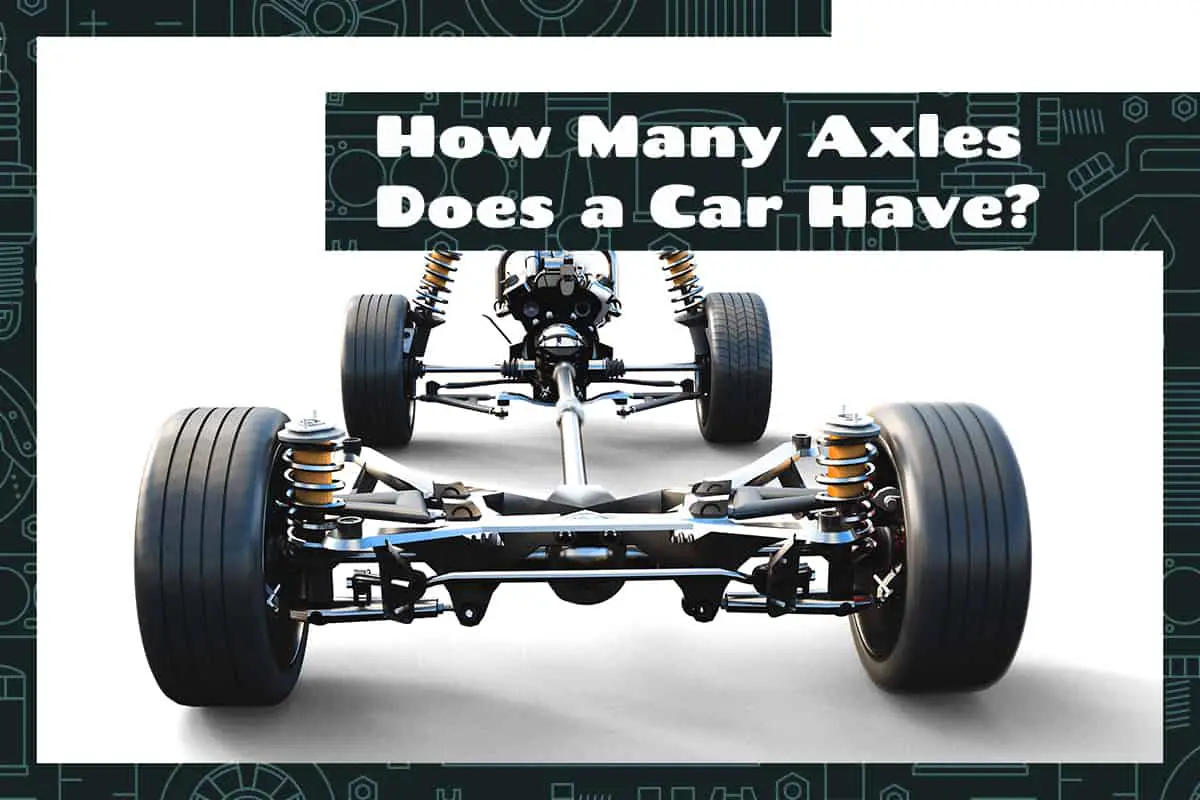

Components of a Car’s Undercarriage

The undercarriage houses various components that contribute to the car’s movement, safety, and performance

1. Suspension System

The suspension system comprises springs, shock absorbers, and struts, functioning to provide a smooth ride. By absorbing road shocks and bumps, it keeps the car stable and ensures wheel adherence to the road.

2. Chassis Frame

Serving as the vehicle’s backbone, the chassis frame supports the car’s body and all its components. Made typically of steel, it’s designed for strength and rigidity.

3. Brake System

Located near the wheels, the brake system includes discs, pads, and calipers. Activating the brakes squeezes the pads against the discs, producing friction, which slows down or stops the vehicle.

4. Axles

These are rod-like components connecting a pair of wheels. In most cars, there are two axles – one for the front wheels and one for the rear. They transmit power from the engine to the wheels and help in steering and braking.

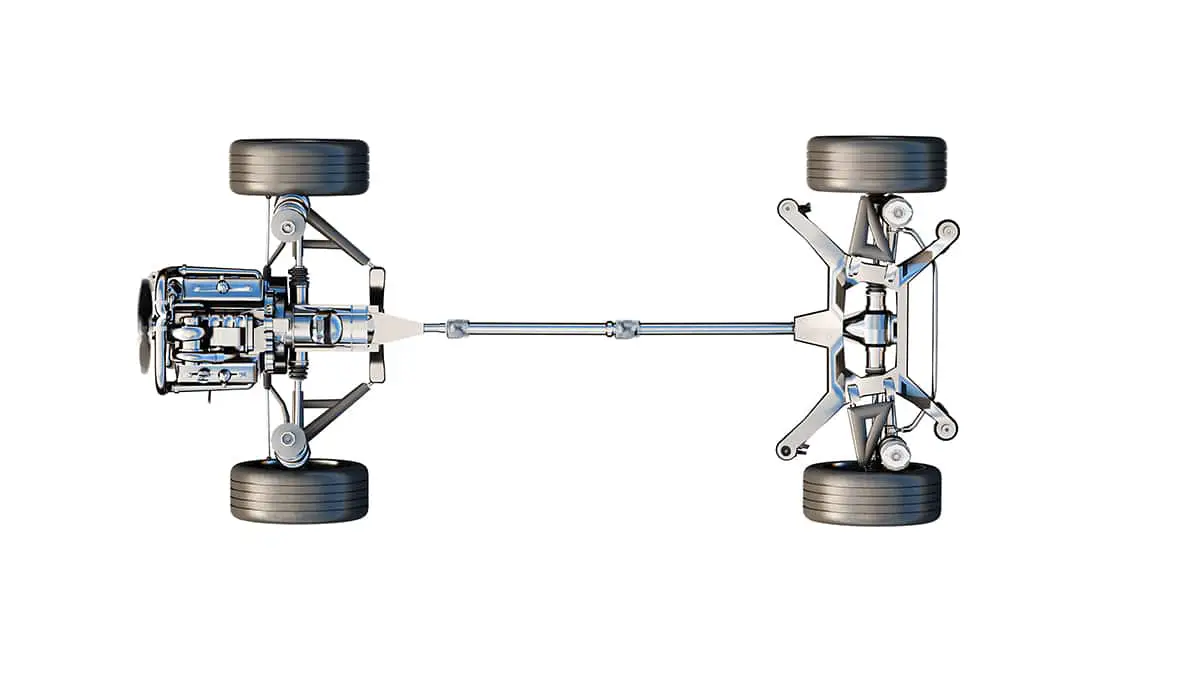

Axle Configurations: Types and Purposes

Axles have a significant role in the distribution of power and driving comfort. The type of axle a vehicle has directly influences how it handles on the road.

Live Axles vs. Dead Axles

A vehicle’s axles can be broadly categorized into two main types: live axles and dead axles.

- Live Axles: Also known as drive axles, live axles transfer power from the engine to the wheels. These are commonly found in rear-wheel-drive vehicles. When the engine runs, it sends power to the live axle, which in turn moves the wheels.

- Dead Axles: Unlike live axles, dead axles don’t transfer any power. They serve merely as a support for the weight of the vehicle and its cargo. You’ll often find dead axles in the front of trucks or in trailers, where no drive power is needed.

Front Axles

The front axle is pivotal, quite literally, for a car’s steering mechanism. It supports the weight of the front part of the vehicle, the engine, and allows for the wheels to rotate and pivot. This axle configuration typically includes:

- Steering Knuckle: Connects the wheel to the suspension, allowing for rotation.

- Wheel Hub: Located in the center of the wheel, it houses the wheel bearings.

Rear Axles

Rear axles are common in rear-wheel-drive vehicles and bear the responsibility of transferring power from the engine to the rear wheels. They’re built robustly since they not only support the weight of the vehicle but also manage the torque from the engine. Key components here include:

- Axle Housing: Encases the axle shafts and protects them.

- Differential: Allows the wheels to turn at different speeds, essential for turns.

Tandem Axles

Some vehicles, especially larger trucks, feature tandem axles—two close-set axles either at the front or the rear. This setup offers:

- Increased Weight Support: Distributes the vehicle’s load over a larger surface area.

- Enhanced Stability: Provides better balance, especially when carrying heavy loads.

Independent vs. Solid (Beam) Axles

Vehicles can have either an independent or solid axle setup, each with distinct driving characteristics:

- Independent Axles: In this setup, each wheel on the axle can move independently of the other. This means that if one wheel hits a bump, the other remains unaffected. Cars with independent front suspension offer smoother rides and better handling.

- Solid (Beam) Axles: Here, the wheels are linked, and movement on one side affects the other. These are sturdier and are often found in trucks and off-road vehicles due to their strength and durability.

Common Problems and Maintenance

Axles encounter wear, damage, or other issues, which can compromise driving safety and comfort.

Signs of Axle Wear and Damage

While axles are built to be durable, they’re not immune to wear and tear. Here are some signs indicating potential axle problems:

- Clicking Sounds: If you hear clicking noises while turning, it might be a sign of a worn-out CV joint, which is a part of the axle in many cars.

- Vibrations: Experiencing vibrations during a drive, especially when accelerating, could indicate a damaged axle.

- Grease on the Inner Edge of Tires: If you notice grease around your tires, it could be due to a broken boot releasing the lubricant.

- Difficulty in Steering: If the car pulls to one side or resists turning, it might be time to inspect the axles.

Maintenance Tips

Regular maintenance can mitigate many potential problems. Here are some proactive measures to keep axles in prime condition:

- Regular Inspections: Make it a habit to inspect the axles periodically. Look for signs of rust, cracks, or other damages.

- Lubrication: Ensure the axle components, especially the CV joints, are adequately lubricated. It reduces friction and prevents premature wear.

- Avoid Overloading: Every vehicle has a weight limit. Exceeding this can strain the axles, leading to potential damage.

- Mind the Road: Driving on rough terrains or over potholes can impact the axles. Being cautious and driving smoothly can reduce the chances of damage.

The Cost of Axle Repair and Replacement

The expenses associated with axle repairs can vary based on the vehicle type, extent of the damage, and the region:

- Minor Repairs: Fixing minor issues, like a torn boot or adding lubrication, can be relatively inexpensive.

- Major Repairs: Addressing problems like bent axles or damaged CV joints can be costlier. In some cases, replacing might be more economical than repairing.

- Replacement: Depending on the make and model of the car, brand-new axles can come at a higher price tag. However, in situations where damage is extensive, replacement is often the best option.

FAQs

1. Why do some trucks have more axles?

Trucks vary in design and purpose, and the number of axles often reflects their intended function. Some reasons for multiple axles in trucks include:

- Weight Distribution: Trucks are designed to carry heavy loads. More axles allow for better weight distribution across the vehicle’s structure, preventing undue stress on any single axle and providing added stability.

- Improved Traction: More axles can mean more wheels touching the ground. This can improve traction, which is especially valuable for trucks that drive on uneven or slippery terrains.

- Maneuverability: Some trucks have additional axles that can be raised or lowered. When not carrying heavy loads, these extra axles can be lifted to save tire wear and improve fuel efficiency. When needed, they can be lowered for better weight distribution.

2. How far can I drive on damaged axles?

Driving on damaged axles is not recommended. Continuing to drive with a compromised axle can cause further damage to other parts of the vehicle, like the differential, transmission, or wheels. Damaged axles can lead to loss of vehicle control, especially when driving at high speeds or during turns.

3. When should I replace my axles?

There are scenarios when a replacement might be necessary:

- After an Accident: If your vehicle has been involved in a significant collision, it’s a good idea to get the axles inspected. Any bends, cracks, or distortions might necessitate a replacement.

- Corrosion: In regions with harsh winters or where salt is used on roads, axles can be prone to rust and corrosion. If the corrosion is extensive, replacing the axle might be the best option.

- Based on Mileage: While there’s no strict mileage after which axles should be replaced, high-mileage vehicles (especially those over 200,000 miles) should have their axles checked regularly for signs of wear.