Engines are the heart of every vehicle, pumping power throughout the system and making motion possible. But like any complex mechanism, they rely on precise coordination to function optimally. Among the many critical components that help maintain this harmony is a process called engine timing, an aspect often misunderstood or overlooked by many automobile enthusiasts.

Engine timing is a process within a vehicle’s engine that synchronizes the movement of the pistons and valves. It ensures that:

- The intake valve opens at the right time to let in the air-fuel mixture

- The mixture is ignited at the correct moment for optimal power

- Exhaust gasses are expelled efficiently

This article will delve into the fundamentals of engine timing, its crucial role, the components involved, and how it works.

Basics of an Internal Combustion Engine

The internal combustion engine is the powerhouse of your vehicle. It converts fuel into mechanical energy, which drives the wheels. Key components include cylinders, pistons, valves, and spark plugs.

An engine comprises several cylinders, usually 4, 6, or 8, within which pistons move up and down. The top of the cylinder houses two valves—the intake valve, which allows the air-fuel mixture in, and the exhaust valve, which expels combustion gasses. The spark plug, vital for ignition, sits near these valves.

You can learn more about internal combustion engines in this guide.

Understanding Engine Timing

Engine timing, also known as ignition timing, is the process of synchronizing the opening and closing of engine valves with the movement of the pistons during the four-stroke cycle. Precise timing ensures the air-fuel mix enters the cylinder at the right time, ignites correctly, and exhaust gasses are efficiently expelled.

In a running engine, the timing system commands when the spark plug should ignite the air-fuel mixture (spark timing) and when the valves should open or close (valve timing). Proper synchronization guarantees the engine’s efficient operation and avoids potential engine damage. It also impacts fuel economy and engine longevity.

Engine efficiency directly correlates with correct engine timing. When timing is optimal, the engine utilizes the fuel-air mixture most effectively, yielding maximum power while reducing fuel consumption and harmful emissions. Conversely, incorrect timing can lead to power loss, increased fuel consumption, and excessive wear and tear on engine parts.

Engine timing is adjustable, and adjustments can cater to specific driving conditions. Advanced timing, where the spark plug fires earlier, is beneficial for high-speed driving as it allows more time for combustion. Conversely, retarded timing, where the spark plug fires later, is better for low-speed driving or heavy loads.

Components Involved in Engine Timing

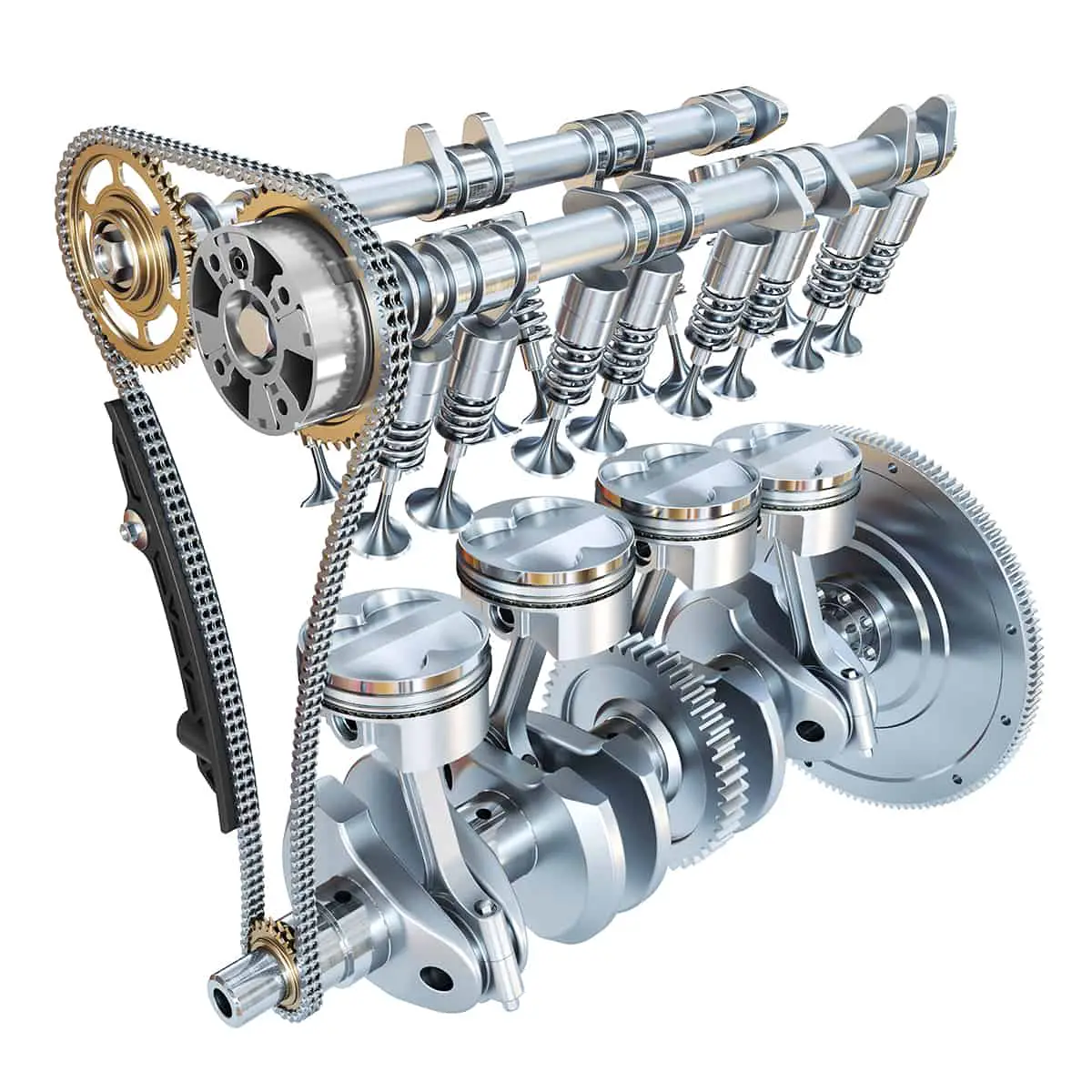

Engine timing is a symphony of components working in harmony to keep your vehicle’s engine running smoothly. The main actors in this ensemble include the timing belt or chain, camshaft, crankshaft, and timing gears.

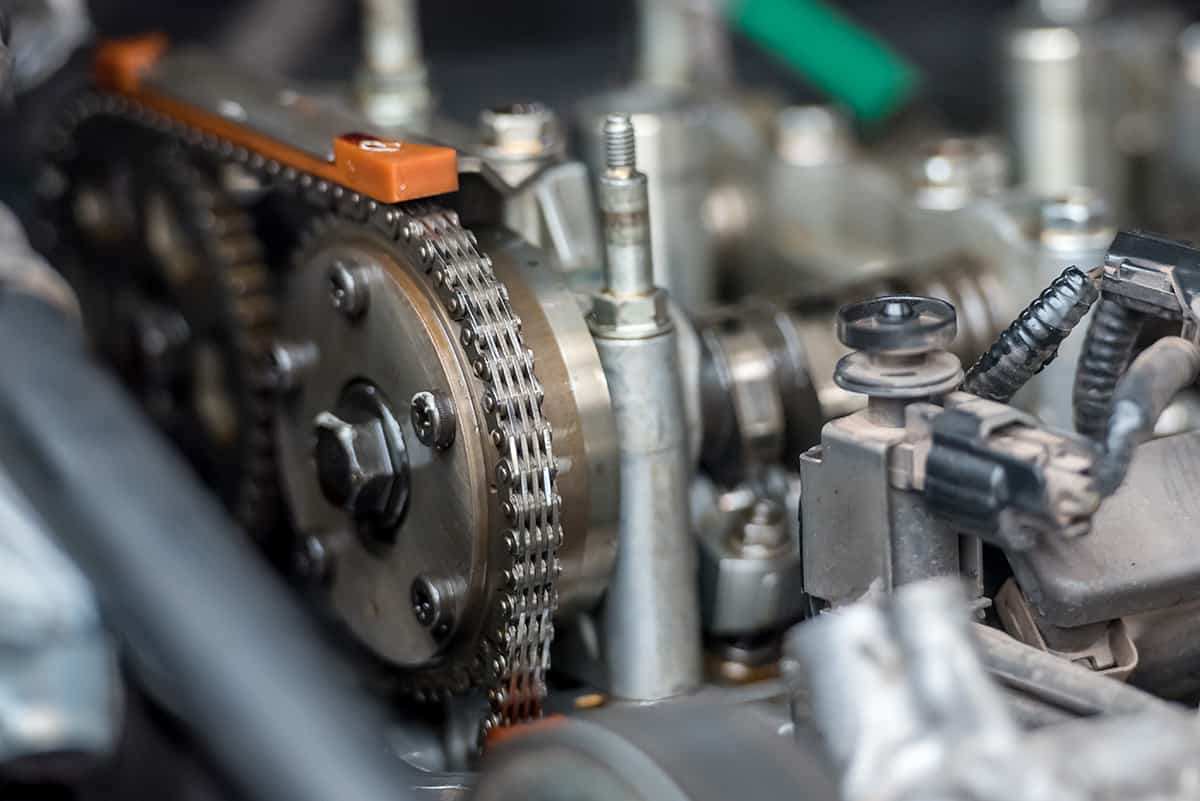

1. The timing belt and chain

The timing belt or chain is made of high-strength rubber or metal links, it connects the crankshaft to the camshaft, ensuring their synchronized operation. The timing belt rotates the camshaft in tune with the crankshaft, maintaining the precise timing required for the four-stroke cycle.

Timing belts require replacement every 60,000 to 100,000 miles, as recommended by the vehicle manufacturer, while timing chains generally last longer. Failure to replace a worn-out timing belt can result in it breaking, causing severe engine damage due to mistimed piston and valve movements.

2. Camshaft and crankshaft

The camshaft and crankshaft are the primary components that the timing belt or chain links. The camshaft, located at the top of the engine, controls the opening and closing of the intake and exhaust valves. It has several lobes (cams) that push against the valves to open them at the correct times.

The crankshaft, positioned at the engine’s bottom, converts the up and down movement of the pistons into rotational motion that drives the vehicle’s wheels. The crankshaft’s position and speed of rotation dictate the timing of the piston movements.

The timing belt or chain ensures that the camshaft and crankshaft rotate in synchrony. This synchrony is critical as it determines when the valves open or close in relation to the pistons’ positions, directly impacting the engine’s efficiency and performance.

3. Timing gears

Timing gears are an alternative to timing belts and chains, mostly found in older vehicles. They connect the camshaft and crankshaft directly and use gear-to-gear contact to maintain engine timing.

One significant advantage of timing gears over belts and chains is their durability. Timing gears rarely need replacement due to wear and tear. However, they can be noisy and are less common in modern vehicles that prioritize noise reduction.

Explanation of How Engine Timing Works

Engine timing is a synchronized mechanism involving pistons, valves, and the spark plug. To grasp its workings, we’ll explore both static and dynamic engine timing.

Working of static engine timing

Static timing refers to the initial ignition spark set during the engine’s idle state. It’s usually set according to the manufacturer’s specifications and often requires a timing light, a specialized device for adjusting timing.

The process begins when the engine’s piston is at Top Dead Center (TDC), i.e., the highest point in the cylinder during the compression stroke. Here, the air-fuel mixture is compressed, and the spark plug is about to ignite it. The moment the spark plug fires to ignite this mixture is the point of static timing.

This ignition needs to occur a few degrees before the piston reaches TDC, a measurement referred to as “Before Top Dead Center” (BTDC). This early ignition ensures the expanding gasses from combustion apply maximum force on the piston when it’s just beginning its downward power stroke, thus optimizing engine performance.

Working of dynamic engine timing

Dynamic timing refers to ignition timing adjustments made when the engine is running and adjusting to varying speeds and loads. As the engine’s speed increases, the air-fuel mixture in the cylinders doesn’t have enough time to combust fully if the spark timing remains static. Hence, to ensure complete combustion and optimize engine performance, the ignition spark is advanced—i.e., it’s set to occur earlier in the piston’s compression stroke.

This advancement is achieved through a mechanism usually controlled by the engine’s Electronic Control Unit (ECU) in modern vehicles, taking into account several parameters like engine speed, load, temperature, and throttle position. On the other hand, when the engine slows down or operates under lighter loads, the ignition spark is delayed to prevent engine knocking.