The heart of your vehicle is its engine, a complex maze of components working in harmony to keep you moving. Among these parts, the Positive Crankcase Ventilation (PCV) valve may seem minor, but its role is crucial.

This seemingly insignificant part is a key player in maintaining your vehicle’s health, performance, and emission control. However, like any other component, it can fail, leading to a series of potential issues.

Positive Crankcase Ventilation (PCV) is a system that removes harmful vapors from the engine and redirects them into the combustion chamber to be burned off. Symptoms of a failing PCV valve include:

- Decreased fuel efficiency

- Engine misfires and rough idling

- Oil leaks and sludge build-up

- Increased exhaust emissions

In this guide, we’ll delve deeper into the vital role of the PCV valve, the telltale signs of a failing one, and how it affects your vehicle’s performance. We’ll also guide you on how to replace a bad PCV valve and the financial implications involved.

The Role and Mechanism of a Positive Crankcase Ventilation (PCV) Valve

In simple terms, a PCV valve’s primary function is to regulate the flow of harmful gasses or blow-by gasses from the engine’s crankcase to the intake manifold. Blow-by gasses are generated when small amounts of combustion gasses slip past the piston rings into the engine’s crankcase.

These gasses are a mix of unburned fuel, air, and water vapor, which, when combined with the oil mist present in the crankcase, form a corrosive mixture. If not properly managed, these gasses can build up and cause engine damage by promoting the formation of sludge or diluting engine oil, leading to increased wear.

The PCV valve operates in a simple yet effective way. It’s essentially a one-way valve that opens and closes in response to the engine vacuum. Let’s break down how it works step by step:

- Engine Idle or Deceleration: During these periods, the engine’s vacuum level is at its highest. The vacuum draws the PCV valve’s plunger in, reducing the opening size, which in turn minimizes the amount of crankcase gasses entering the intake manifold. This action prevents the engine from running too lean, which could damage it.

- Normal or High-Speed Engine Operation: Under these conditions, the engine’s vacuum level drops. The PCV valve’s spring pushes the plunger back, increasing the opening size. This action allows more gasses to be drawn out of the crankcase and into the intake manifold.

- Engine Backfire or Shutdown: If a backfire occurs or when the engine is turned off, there is no vacuum present. The spring forces the plunger to close the PCV valve entirely, preventing any backward flow of gasses or flame from reaching the crankcase.

Recognizing a Bad or Failing PCV Valve

A PCV is subject to wear and tear, which could lead to failure. The key to avoiding severe engine damage lies in being able to recognize the symptoms of a bad or failing PCV valve. Below are the most common symptoms and potential causes linked to a malfunctioning PCV valve.

1. Decreased Fuel Efficiency

When the PCV valve is stuck open, it creates a lean mixture of air and fuel, which the engine compensates for by adding more fuel. This could lead to increased fuel consumption, thus decreasing fuel efficiency.

On the other hand, if the PCV valve is stuck closed, it can result in a rich fuel mixture, where too much fuel and not enough air is present. Although the engine may not compensate by adding fuel in this case, a rich mixture can decrease fuel efficiency by causing the engine to run poorly.

2. Engine Misfires and Rough Idling

Another common symptom of a bad PCV valve is engine misfires or rough idling. If your vehicle feels like it’s running unevenly, shaking, or vibrating excessively while idling, a failing PCV valve might be the culprit.

When the PCV valve isn’t working correctly, the engine vacuum can’t properly control the release of blow-by gasses. This improper release can lead to pressure buildup, causing your engine to misfire or idle roughly.

3. Engine Oil Leaks and Sludge

If the valve is stuck closed, the pressure of the blow-by gasses builds up in the crankcase. Over time, this pressure can lead to oil being forced out of the engine, resulting in oil leaks.

In addition to leaks, a malfunctioning PCV valve can also cause engine oil sludge. Blow-by gasses contain contaminants that can mix with engine oil over time. When these contaminants aren’t properly vented out by a functioning PCV valve, they can mix with the oil, leading to sludge buildup. This buildup can clog the oil passages and lead to severe engine damage.

4. Increased Exhaust Emissions

The PCV valve’s role is to route blow-by gasses back to the engine, where they are burned off. If the PCV valve isn’t functioning correctly, these gasses escape into the environment instead of being burned off. This escape not only contributes to pollution but could also lead to your vehicle failing an emissions test.

Replacing a Bad or Failing PCV Valve

Replacing a PCV valve can be a manageable task, even for those with a basic understanding of automotive mechanics. This step-by-step guide will assist you in replacing your PCV valve effectively and safely.

Tools Needed for PCV Valve Replacement

Before starting the replacement process, gather the necessary tools. These usually include:

- A new PCV valve specific to your vehicle model (Check your vehicle’s manual for the correct part number)

- A wrench or pliers

- A rag or cloth for cleaning

Remember, safety comes first. Make sure your vehicle is off and cool before you start to prevent any accidental burns or other injuries.

Steps to Safely and Effectively Replace a PCV Valve

Here’s a step-by-step process on how to replace your PCV valve:

- Locate the PCV Valve: The PCV valve is typically located on the engine valve cover. It’s a small plug or cylinder connected to a rubber hose. If you’re struggling to locate it, refer to your vehicle’s manual for specific guidance.

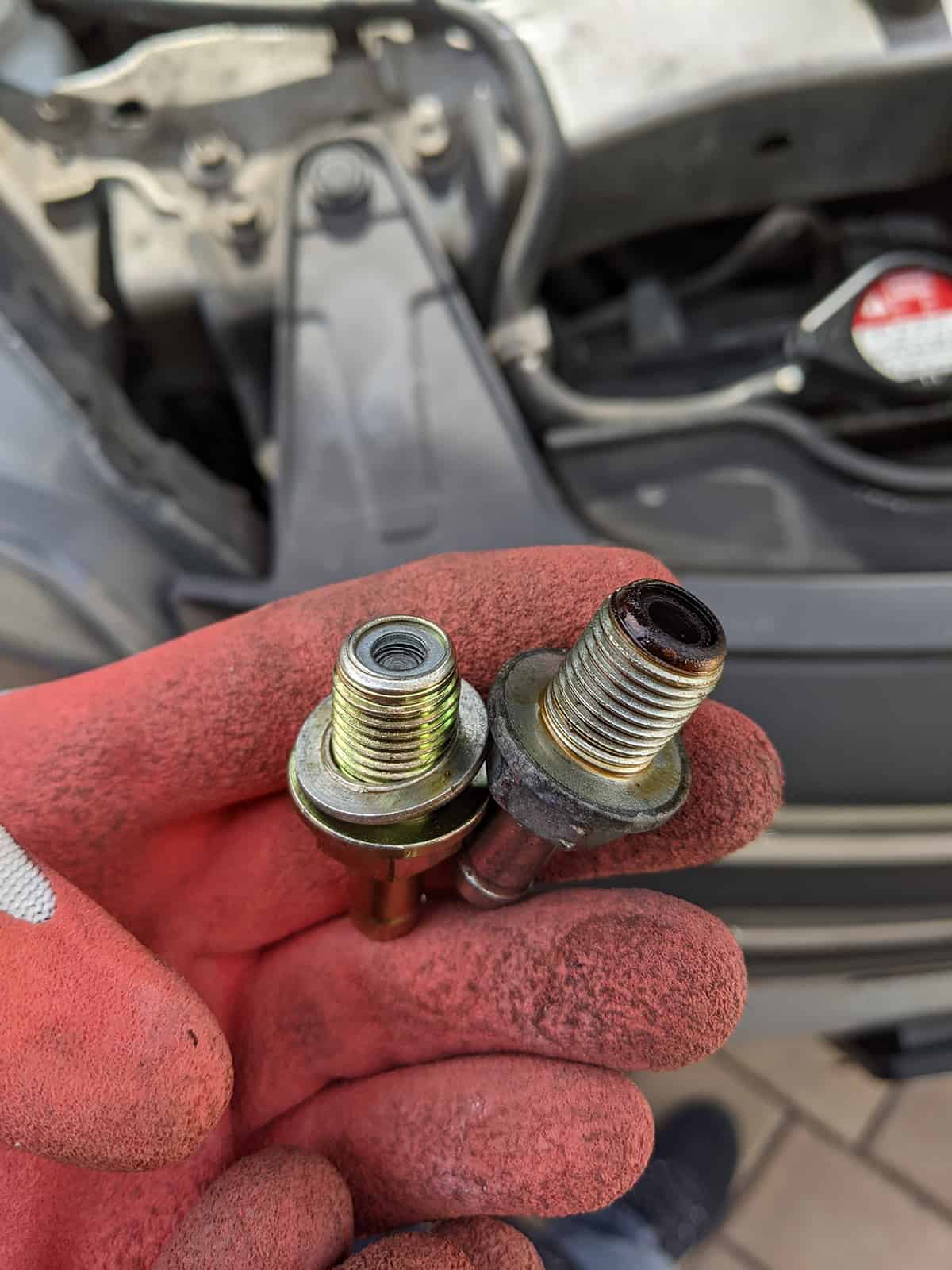

- Remove the Old PCV Valve: Once located, the PCV valve can usually be removed by twisting it counterclockwise. Depending on the make and model of your vehicle, you may need a wrench or pliers to loosen the valve. Once loose, you should be able to pull the valve out of its rubber grommet in the valve cover.

- Inspect and Clean the Area: Before installing the new valve, inspect the area for any signs of oil leaks, cracks, or other damage. Use a clean rag to wipe away any oil or dirt buildup.

- Install the New PCV Valve: Place the new valve into the rubber grommet and twist it clockwise to secure. Be careful not to overtighten it as it may cause damage. Reconnect the hose to the PCV valve.

- Check the Installation: Once installed, give the valve a gentle tug to ensure it’s secure. Start your vehicle and let it run for a few minutes. Check around the PCV valve for any leaks and listen for any unusual sounds.

Cost Implications of Replacing a Failing PCV Valve

The cost of a new PCV valve can vary significantly depending on the make and model of your vehicle. Typically, a new PCV valve can range from $10 to $100, with most falling between $20 and $50. Be sure to check your vehicle’s manual or consult with a professional to ensure you purchase the correct part for your vehicle.

If you don’t feel comfortable replacing the PVC on your own, you can always go to a mechanic. Labor costs can also vary widely depending on your location and the mechanic or dealership you choose. Replacing a PCV valve is relatively straightforward and often takes less than an hour. As of the time of writing, you can expect to pay between $50 and $150 in labor costs for PCV valve replacement.