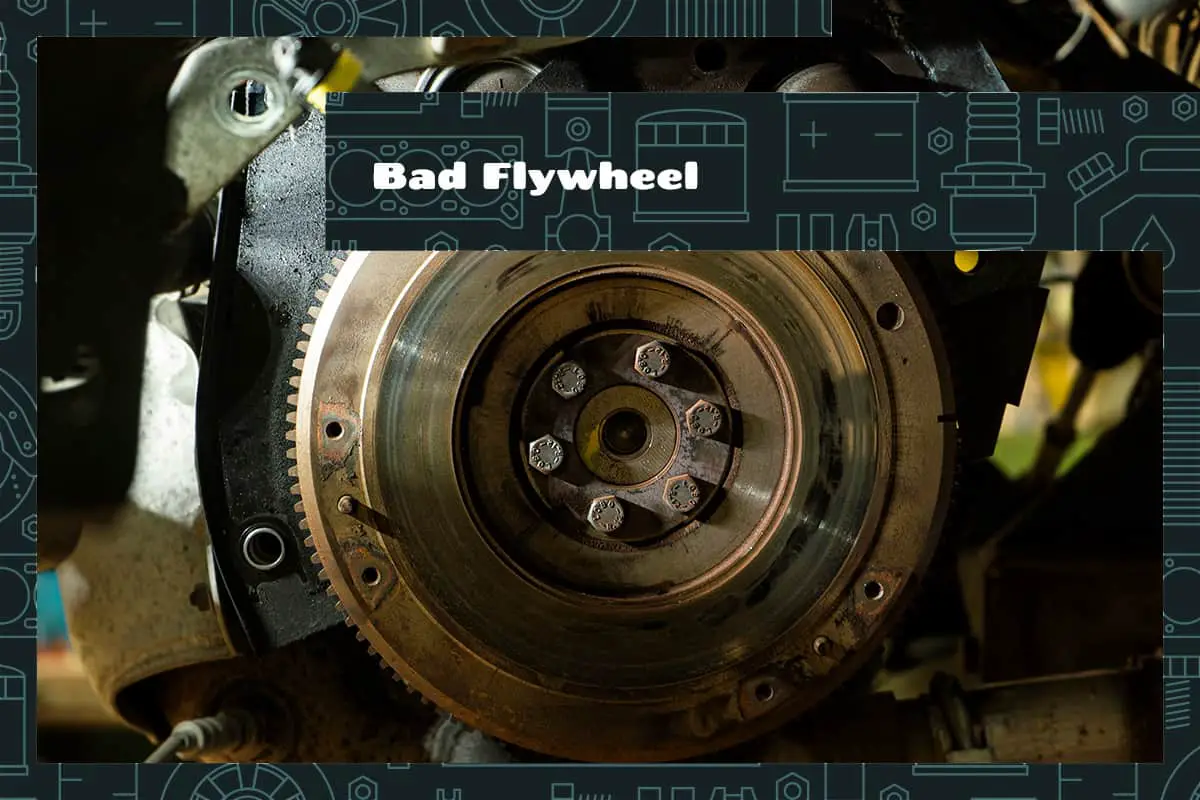

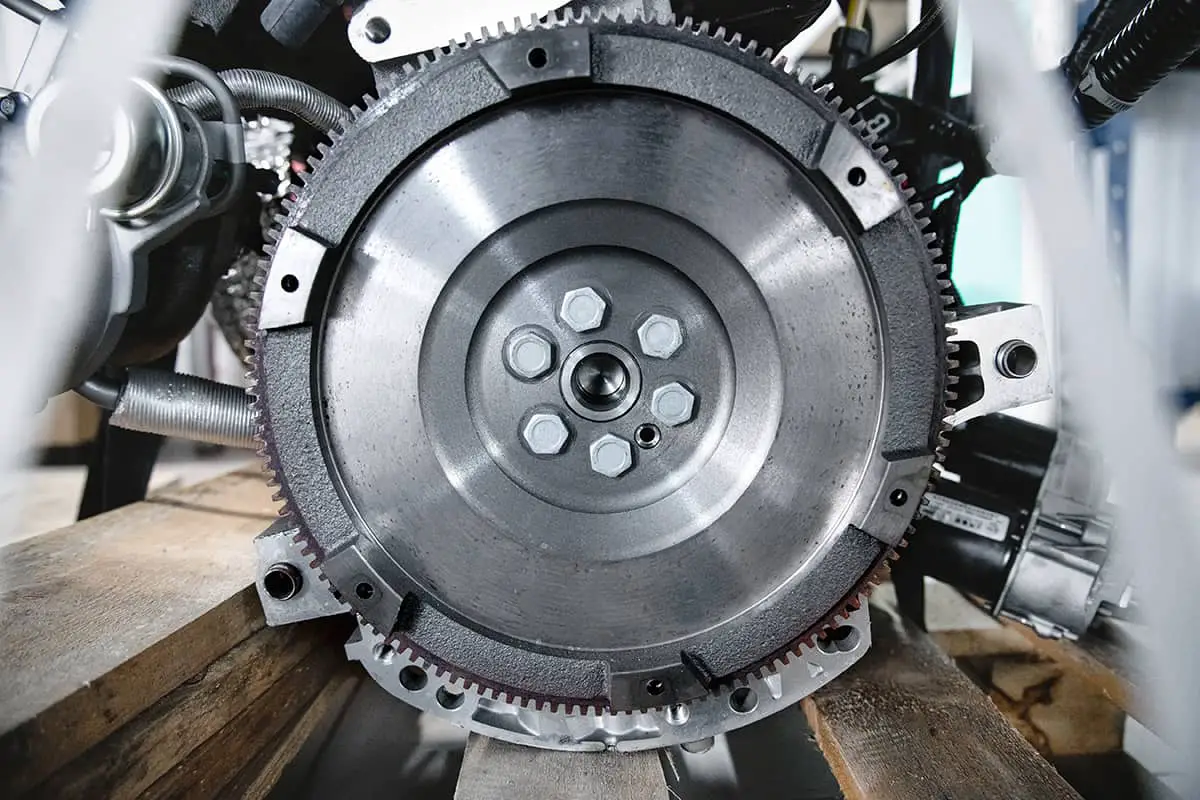

In the vast and complex world of automotive mechanics, the flywheel stands as a critical component, often overlooked. This spinning mechanical device stores rotational energy, providing the necessary momentum for the gears to engage smoothly and your car to drive seamlessly.

However, like any other part of your car, the flywheel can become damaged or wear out over time, affecting your vehicle’s performance and lifespan.

The symptoms of a bad flywheel can be diverse, but there are some key signs to look out for. These include difficulties or stiffness while shifting gears, unexpected gear slippages, unusual clutch vibrations, and peculiar noises, such as rattling or clunking, during gear shifts or when starting the engine.

This guide aims to explore the realm of bad flywheels in detail. It will delve into signs of a bad flywheel and fixing issues.

Deep Dive into Flywheel Mechanics

An essential cog in the complex machinery of a vehicle, the flywheel is a marvel of engineering designed to ensure smooth, uninterrupted vehicle operations. Understanding its mechanics requires a detailed look into its components and functionality, as well as the role it plays within the entire vehicle’s system.

Anatomy of a Flywheel

The flywheel is a heavy metal disk located between the engine and transmission. The flywheel’s primary components include the body (also known as the “mass”), the ring gear, and the friction surface.

The body, typically made of iron or steel, makes up most of the flywheel’s mass. The substantial weight helps maintain the engine’s momentum while it’s running. The body also has an attached ring gear, which is the outermost part of the flywheel. The starter motor engages this ring gear to start the engine.

The friction surface, a flat area on one side of the flywheel, comes into direct contact with the clutch disc during gear shifting. This contact enables the transmission of engine torque to the vehicle’s drivetrain.

How a Flywheel Works in a Vehicle

Energy Storage: The flywheel acts as a mechanical battery, storing rotational energy. When the engine is running, it turns the flywheel. Due to its mass, the flywheel resists changes in speed. When the engine’s pistons fire unevenly, the flywheel uses its stored energy to maintain a constant rotational speed. This results in smoother engine operation and protects against engine lugging or stalling.

Torque Transmission: When you change gears, the clutch disc and the flywheel’s friction surface engage. This engagement transmits the engine’s torque to the vehicle’s transmission, ensuring smooth gear shifts. When you depress the clutch pedal, it disengages the clutch disc from the flywheel, breaking the torque transmission and allowing for a smooth gear change.

The Indications of a Bad Flywheel

Detecting a failing or damaged flywheel early can save you from costly repairs or even a breakdown. Knowing what to look for can help ensure your vehicle continues to provide reliable service.

How to Identify a Failing Flywheel

- Gear Slippage: If your vehicle unexpectedly slips out of gear, it could be due to an issue with your flywheel. A damaged or worn flywheel can prevent the clutch from working correctly, leading to problems with gear engagement.

- Vibrations: Unusual vibrations from your clutch, especially when the clutch pedal is engaged, could be a sign of a bad flywheel. These vibrations are typically due to uneven friction surface on the flywheel, caused by warping or cracking.

- Burning Smell: A distinctive burning smell, akin to burning rubber or electrical wiring, can indicate a bad flywheel. This odor can be due to excessive heat from friction between the clutch plate and the flywheel.

- Difficulty Shifting Gears: If you experience difficulty or stiffness when shifting gears, it may be a sign that your flywheel is in trouble. This problem can occur if the flywheel surface becomes warped or uneven.

- Noise: Unusual noises like rattling or clunking, especially during gear shifts or when starting the engine, can point to a flywheel problem. Such sounds might result from a loose or broken flywheel.

How a Bad Flywheel Affects Your Vehicle

A bad flywheel can significantly affect your vehicle’s performance and overall driving experience:

- Reduced Fuel Efficiency: A bad flywheel can lead to a decrease in fuel efficiency. If the flywheel is not functioning correctly, it can make the engine work harder, consuming more fuel.

- Poor Vehicle Performance: Issues with the flywheel can lead to engine vibrations, gear slippage, and problems with clutch operation. These issues will inevitably affect your vehicle’s overall performance.

- Potential Damage to Other Components: A failing flywheel doesn’t operate in isolation. The excess heat and vibrations can damage other components, including the transmission and clutch system.

Causes of Flywheel Damage

Given the critical role a flywheel plays in your vehicle’s performance, it’s important to know the common culprits behind its wear and tear or failure.

1. Excessive Heat and Clutch Overuse

As the friction surface of the flywheel and the clutch disc come into contact, heat is produced. If the clutch is engaged and disengaged excessively—especially in stop-and-go traffic or during aggressive driving—the resulting heat can cause the flywheel’s surface to warp or develop hot spots. In extreme cases, this can even lead to the flywheel cracking.

2. Inadequate Maintenance

Neglecting regular vehicle maintenance can take a toll on the flywheel. For example, failing to replace the clutch disc when needed can result in excessive wear and tear on the flywheel. Similarly, not replacing a worn-out transmission bearing can lead to imbalances that can damage the flywheel.

3. Severe Driving Conditions

Your driving habits and the conditions in which you drive can also influence the life of your flywheel. Regularly driving in heavy traffic, towing large loads, or off-roading can put extra stress on the flywheel, potentially leading to damage over time.

4. Natural Wear and Tear

Like any mechanical component, the flywheel will naturally wear out over time. Every time you shift gears, the clutch disc and the flywheel engage, causing some wear on the friction surface.

How to Address a Bad Flywheel

Facing a bad flywheel is not an ideal situation, but knowing how to respond can make a significant difference. From initial diagnosis to potential solutions, understanding the process can help you make informed decisions regarding your vehicle’s maintenance.

Diagnosing a Bad Flywheel

- Visual Inspection: Mechanics might conduct a visual inspection to check for visible signs of damage like cracks, burns, or hot spots on the flywheel’s surface.

- Noise Identification: Listening to the noises your car makes can help pinpoint the problem. Specific noises, like rattling or clunking, are often associated with flywheel issues.

- Clutch Function Test: By testing the clutch’s operation, a mechanic can determine whether a faulty flywheel is causing problems with gear shifts.

Repair or Replacement?

Once the problem is diagnosed, you’ll need to decide between repair or replacement. This decision depends on the extent of the damage:

- Resurfacing: If the damage is minor, such as slight warping or the presence of hot spots, the flywheel might be resurfaced. This process involves machining the flywheel’s surface to make it smooth and even again.

- Replacement: However, if the flywheel is cracked, severely warped, or excessively worn, it will likely need to be replaced. Replacement is also the usual course of action if the flywheel’s teeth (used to engage the starter motor) are damaged.

The Process of Flywheel Replacement

Replacing a flywheel is a complex job that typically involves the following steps:

- Removal of Components: The mechanic will need to remove several components to access the flywheel, including the transmission and clutch.

- Flywheel Removal and Replacement: Once accessed, the old flywheel is removed, and the new one is installed. You should know that the new flywheel’s bolts need to be torqued properly to prevent future issues.

- Reinstallation of Components: The removed components are reinstalled, and the clutch operation is tested.