The world of automotive technology is vast and multifaceted, with countless components and mechanisms working in harmony to keep our vehicles moving. Among these parts, the transmission system, specifically the output shaft, plays an integral role. This crucial component functions as the backbone of vehicle motion, turning the wheels and enabling forward or backward movement.

The output shaft is a key part of the transmission system that transfers the rotational force from the engine to the wheels. Its function is pivotal, as it effectively converts and channels the power generated by the engine into motion that propels the vehicle.

This article will delve deeper into the intricacies of the transmission output shaft. It will elucidate the role of the output shaft in a transmission and examine the impact of output shaft problems.

Introduction to the Transmission System

Vehicle transmission is a critical aspect of automotive engineering. Its fundamental purpose is to transmit the engine’s power to the wheels, allowing the car to move. The transmission adjusts the power produced by the engine to match the vehicle’s speed, road conditions, and driver input. It’s a complex system composed of numerous interconnected parts, such as the gearbox, clutch or torque converter, and different types of shafts.

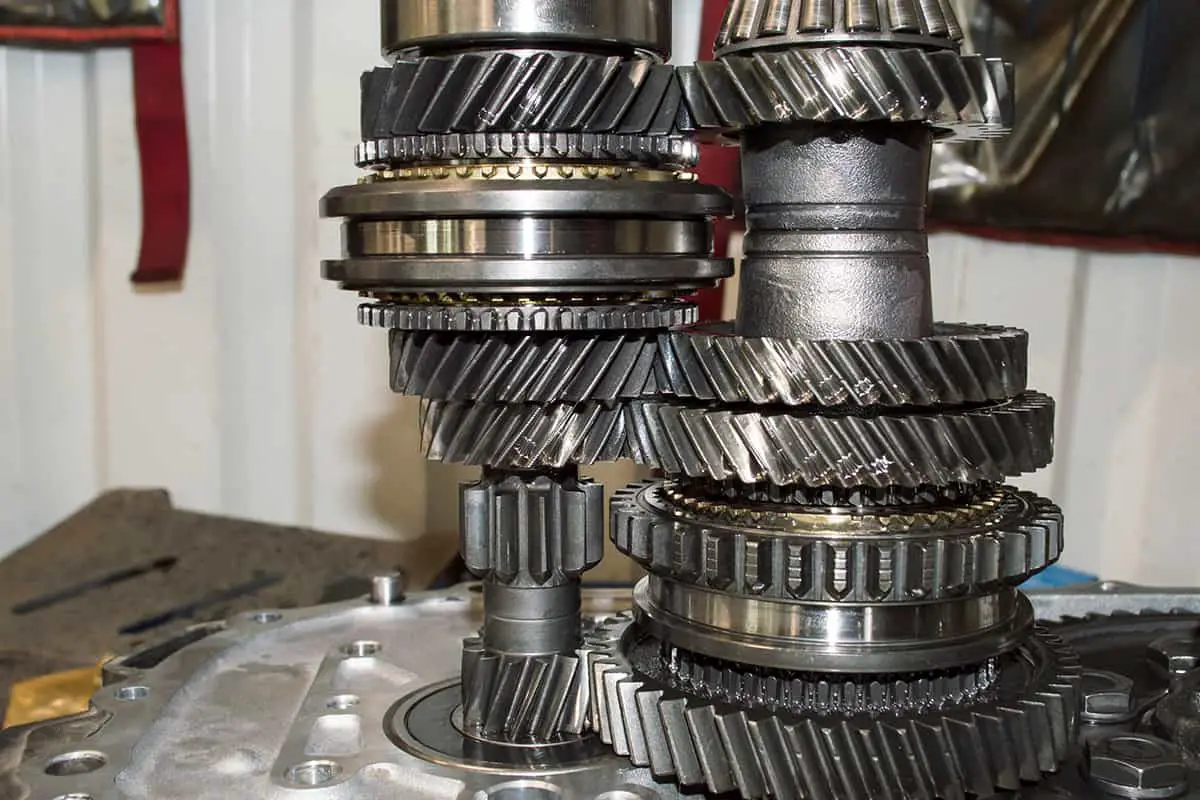

Components of a Transmission

This section will break down the primary parts of a transmission system: the gear selector, input shaft, output shaft, and clutch or torque converter.

1. Gear Selector

The gear selector, often referred to as the shift lever, is the tool through which the driver can manually switch between gears in the transmission. This can be located either on the steering column or the center console of the vehicle.

In automatic transmissions, the gear selector allows you to choose between Park (P), Reverse (R), Neutral (N), and Drive (D) modes, while in manual transmissions, it lets you shift between various numbered gears.

2. Input Shaft

The input shaft is the part of the transmission system that receives power directly from the engine. It’s connected to the clutch or torque converter, which determines the amount of engine power transmitted based on the gear selected. The input shaft carries the engine’s power into the gearbox, where it’s adjusted to the appropriate level based on the speed and torque requirements of the vehicle.

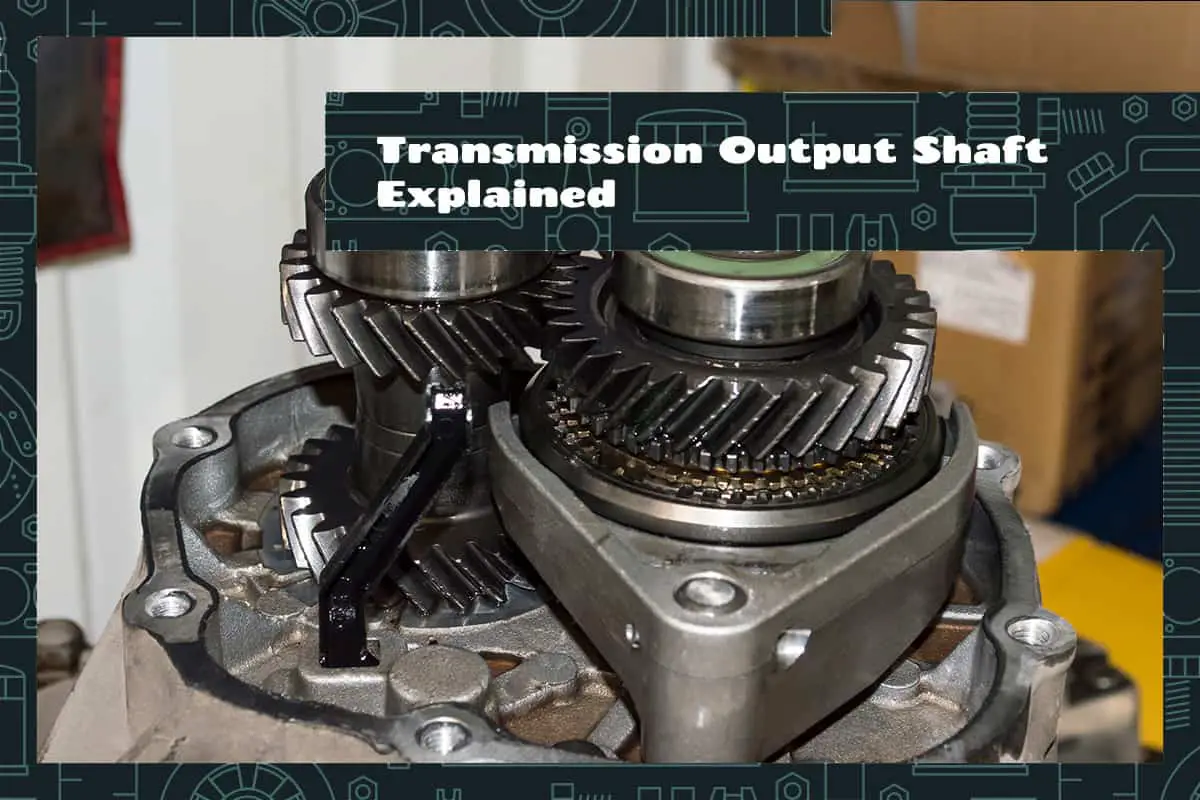

3. Output Shaft

Following the input shaft in the power transmission process is the output shaft. It receives power from the input shaft, reduced to a manageable speed by the gearbox, and channels it to the wheels. An output shaft is essentially a conversion tool; it transforms the high-speed, low-torque force from the engine into low-speed, high-torque power suitable for wheel rotation.

4. Clutch or Torque Converter

In manual transmissions, the clutch disconnects the transmission from the engine when changing gears, preventing the engine from stalling. The driver engages and disengages the clutch pedal manually during this process.

Automatic transmissions, however, use a torque converter instead of a clutch. The torque converter uses hydraulic fluid to transmit engine power to the transmission. It automatically disconnects and connects the engine and the transmission, eliminating the need for the driver to do so manually.

The Role of the Output Shaft in a Transmission

In the complex universe of automotive mechanics, the output shaft is a critical player in the transmission system. Its primary function is to transmit power from the engine to the wheels, but it also has a significant impact on vehicle speed and performance.

How the Output Shaft Works

The output shaft sits at the heart of the transmission system, serving as the final stage in the transmission of power from the engine to the wheels. It receives power from the input shaft, already reduced to a manageable speed by the gearbox. This power, now converted into rotational force, is then transmitted to the wheels, driving the vehicle forward or backward.

The output shaft does not work in isolation. It is connected to various other components of the transmission system. This includes gears of different sizes that can be engaged or disengaged to control the vehicle’s speed and torque.

Connection Between Output Shaft and Differential

The output shaft’s role does not end with merely receiving power from the gearbox. Once the output shaft has the power, it needs to transmit this force to the wheels, and this is where the differential comes into play.

The differential is a device that splits the engine’s torque two ways, allowing each output to spin at a different speed. It connects to the output shaft and manages the distribution of power between the wheels. This is particularly crucial during turning when the wheels need to spin at different speeds to maintain control and efficiency.

The Impact of Output Shaft on Vehicle Speed

An essential characteristic of the output shaft’s role is its impact on the vehicle’s speed. The different gears connected to the output shaft correspond to different speeds, with each gear designed to handle a specific range of speeds.

In simple terms, lower gears (like first or second gear) are used at lower speeds. They provide more torque but less speed. This is why you typically use lower gears for city driving or when climbing a hill.

On the other hand, higher gears (like fourth or fifth gear) are used at higher speeds. They provide less torque but more speed, making them ideal for highway or open-road driving.

Transmission Output Shaft Problems and Solutions

While the output shaft is designed to withstand extensive usage and challenging conditions, it is not immune to problems. Identifying and resolving issues early can prevent further damage to the transmission system and your vehicle as a whole.

Identifying Output Shaft Problems

Detecting output shaft problems can be challenging, primarily because the symptoms often resemble issues related to other parts of the transmission system. However, specific signs suggest a possible output shaft issue:

- Difficulty in Changing Gears: If you’re experiencing trouble while changing gears, it might be an output shaft issue, particularly if you hear grinding noises during the process.

- Unusual Noise: An unusual noise, especially when the vehicle is moving, can indicate an issue with the output shaft. This could be a result of worn bearings or gear teeth.

- Leaking Transmission Fluid: A leak in the output shaft seal can cause transmission fluid to leak, which can lead to multiple other problems if not addressed promptly.

Common Output Shaft Issues

Once you identify the signs of a potential problem, the next step is to understand the common output shaft issues that could be causing these symptoms.

- Worn Out Bearings: The output shaft relies on bearings for smooth operation. Over time, these bearings can wear out, causing the shaft to move irregularly and create unusual noise.

- Damaged Gear Teeth: The gear teeth on the output shaft are subject to significant wear and tear. If they get damaged, it can hinder the smooth transmission of power from the engine to the wheels.

- Faulty Output Shaft Seal: The output shaft seal prevents transmission fluid from leaking. A faulty seal can lead to fluid leakage, which may result in inefficient transmission operation.

Solutions to Output Shaft Problems

Now that we’ve identified the problems, it’s time to explore the solutions:

- Replacing Worn-Out Bearings: If the output shaft bearings are worn out, replacing them is usually the best solution. This should be carried out by a professional mechanic to ensure correct installation.

- Repairing or Replacing Damaged Gear Teeth: Damaged gear teeth can sometimes be repaired, but in severe cases, replacement might be necessary. A qualified mechanic should handle this process.

- Replacing a Faulty Output Shaft Seal: To stop transmission fluid leakage, replacing the faulty output shaft seal is often the most effective solution. A professional mechanic should perform this task to prevent further leakage.