Planetary gears are the unsung heroes of the automotive world. Named after this celestial system, they work in unison in our cars. They may be invisible to us, but their impact on our driving experience is profound.

A planetary gear system is a set of gears consisting of a central ‘sun’ gear, surrounded by ‘planet’ gears, all encased within an outer ‘ring’ gear. This system works by transmitting power from the engine to the wheels of a car, controlling speed and direction.

Today, we’re going to discuss the captivating world of planetary gears, exploring their components, how they operate in cars, and their importance in automotive technology.

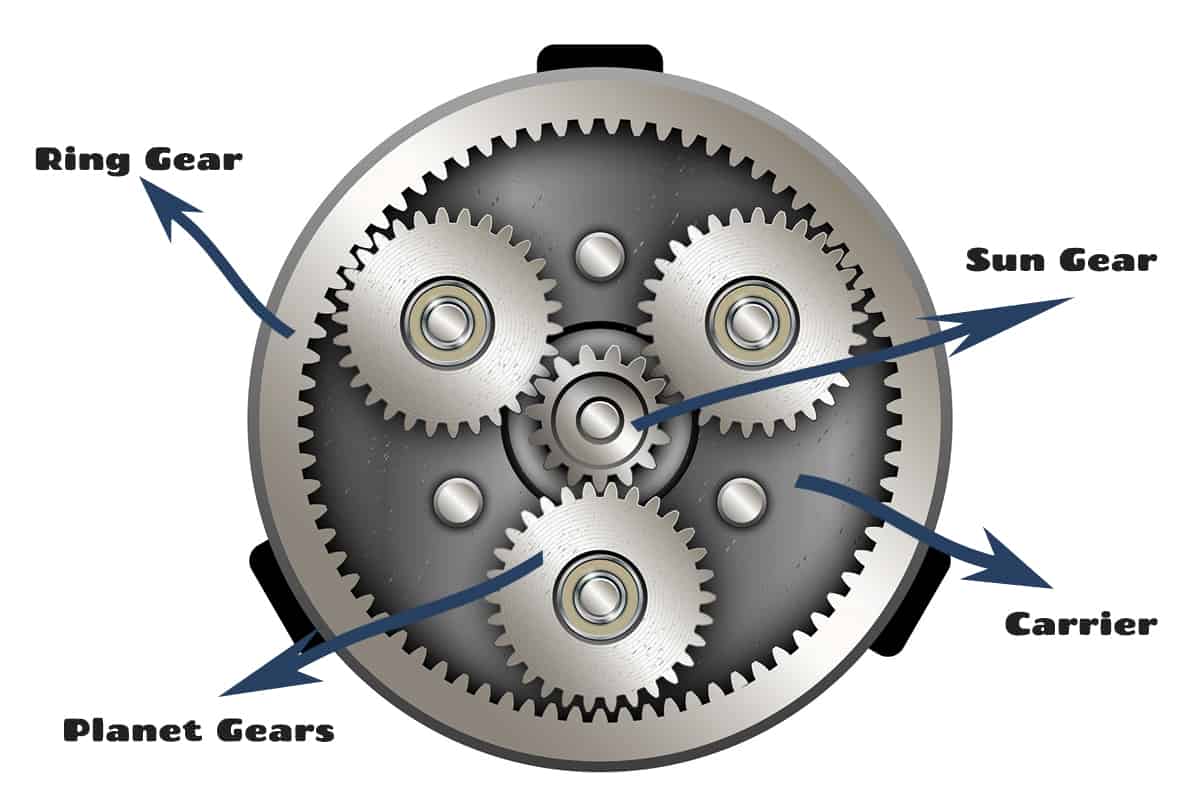

Components of Planetary Gear System

A planetary gear system, which is often found in automatic cars, includes several key parts. Each of these has a specific function, and together they create a system that lets your car run smoothly. Here are the four main components: the sun gear, the planet gear, the ring gear, and the carrier.

Sun Gear

The sun gear sits at the center of the planetary gear system. It’s called the ‘sun gear’ because it is at the center of the gear system. This gear connects to the output shaft of the engine, which is the part that carries power from the engine to the gears. It’s the driving force that sets the other gears in motion.

Planet Gears

Next, we have the planet gears, which are the gears that surround the sun gear. They are named ‘planet gears’ because they ‘orbit’ or revolve around the sun gear, similar to how planets orbit the sun. There are usually two or more planet gears in a system, and they are all mounted on a common component called the carrier. They can spin on their axes and also revolve around the sun gear. They play a significant role in controlling the speed and direction of the vehicle.

Ring Gear

The ring gear, also known as the ‘annulus gear’, forms the outer ring of the planetary gear system. It has inward-facing teeth that mesh with the planet gears. It’s usually connected to the output shaft of the transmission. This means it’s connected to the part of the car that ultimately transfers power to the wheels, allowing the car to move. Depending on which gear is stationary or is providing input or output, the ring gear plays a major role in determining the car’s speed and direction.

Carrier

Finally, the carrier is the component that holds the planet gears in place around the sun gear. It helps the planet gears to revolve around the sun gear while also allowing them to spin on their own axes.

The carrier is usually connected to the output shaft of the transmission in an automatic car. Its primary role is to control the output speed of the transmission, depending on which component (sun gear, planet gears, or ring gear) is fixed or rotating.

Working Mechanism of Planetary Gears

The beauty of a planetary gear system lies in its complex operation. Here, we’ll explore the operation of a planetary gear system and the fascinating process of power transmission.

Detailed Explanation of Power Transmission

In a planetary gear system, power transmission involves the complex interplay of its components. Here’s how it generally works:

- The engine produces power. This power is directed to the transmission of the car, where the planetary gear system resides.

- Within the planetary gear system, the power is initially received by the sun gear. The sun gear begins to spin, which in turn sets the planet gears in motion.

- The planet gears revolve around the sun gear while also spinning on their own axes, thanks to the carrier. As they revolve, they engage with the ring gear.

- Depending on which gear (sun, planet, or ring) is stationary or moving and where the power is being input and output from, different gears or speeds are produced. For example, in some cases, the sun gear might be held stationary, the planet gears might revolve around it, and the ring gear might be the output, leading to a reduction in speed but an increase in torque or rotational force. In other cases, the ring gear might be held stationary while the sun gear is used as the input, leading to an increase in speed but a reduction in torque.

- The output of this system, controlled by the rotations of the gears, is then sent to the wheels of the car through the output shaft of the transmission. This output controls the speed and direction of the car.

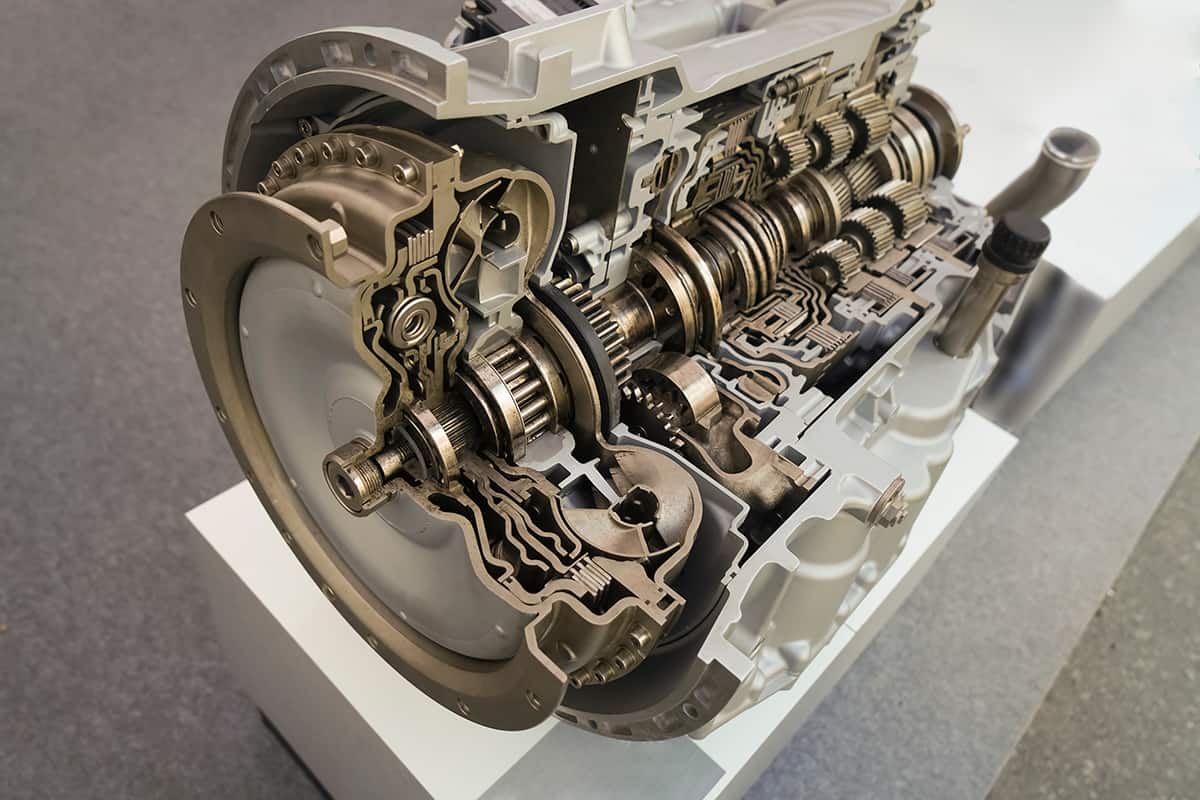

Planetary Gears in Automatic Transmissions

In automatic transmissions, the gear ratios are changed by holding different components of the planetary gear system stationary while allowing others to move. This results in different combinations of speed and power being sent to the wheels. This automatic gear shifting is controlled by a hydraulic system and computer in modern cars, making driving an effortless process.

Planetary Gears in Hybrid and Electric Vehicles

Planetary gears also play a pivotal role in hybrid and electric vehicles. These vehicles need to manage power from different sources, such as an electric motor and a conventional engine, in the case of hybrids. Planetary gear systems are used in these vehicles because they can handle inputs from multiple sources efficiently.

For example, in some hybrid cars, the gasoline engine and electric motor can input power to different components of the planetary gear system, and the system can then combine and manage this power to drive the car. In fully electric vehicles, the planetary gears are used to manage power from the electric motor to the wheels.

Pros and Cons of Planetary Gears

Like everything, planetary gears have their advantages and disadvantages. Let’s look at both sides to get a complete understanding of these complex systems in our cars.

Pros

- Offer a high degree of versatility with the ability to produce different gear ratios from the same set of gears.

- Allow cars to move at various speeds and power levels.

- Compact in design, fitting well into the limited space in cars.

- Enhance durability and longevity by distributing the load across multiple gears.

Cons

- The complex design makes them challenging to manufacture and assemble, potentially increasing vehicle costs.

- Require precision in the alignment and manufacturing of their parts for effective functioning.

- Enclosed gears can be difficult to maintain and repair if issues arise.