When you turn the key or push the start button, a complex process begins that allows your car to spring to life and maintain its operational state. Central to this process is engine compression, a vital phase in the combustion cycle that ensures your vehicle’s power and efficiency.

Low engine compression is a condition where the engine’s cylinders don’t sufficiently compress the air-fuel mixture, resulting in a power drop. Symptoms include power loss, unusual engine noises, and frequent misfires. Repair options range from replacing worn-out piston rings to extensive engine overhauls.

In this article, we will take a closer look at low engine compression. We’ll also explain the causes, elaborate on the symptoms, and explore possible solutions.

What Is Engine Compression?

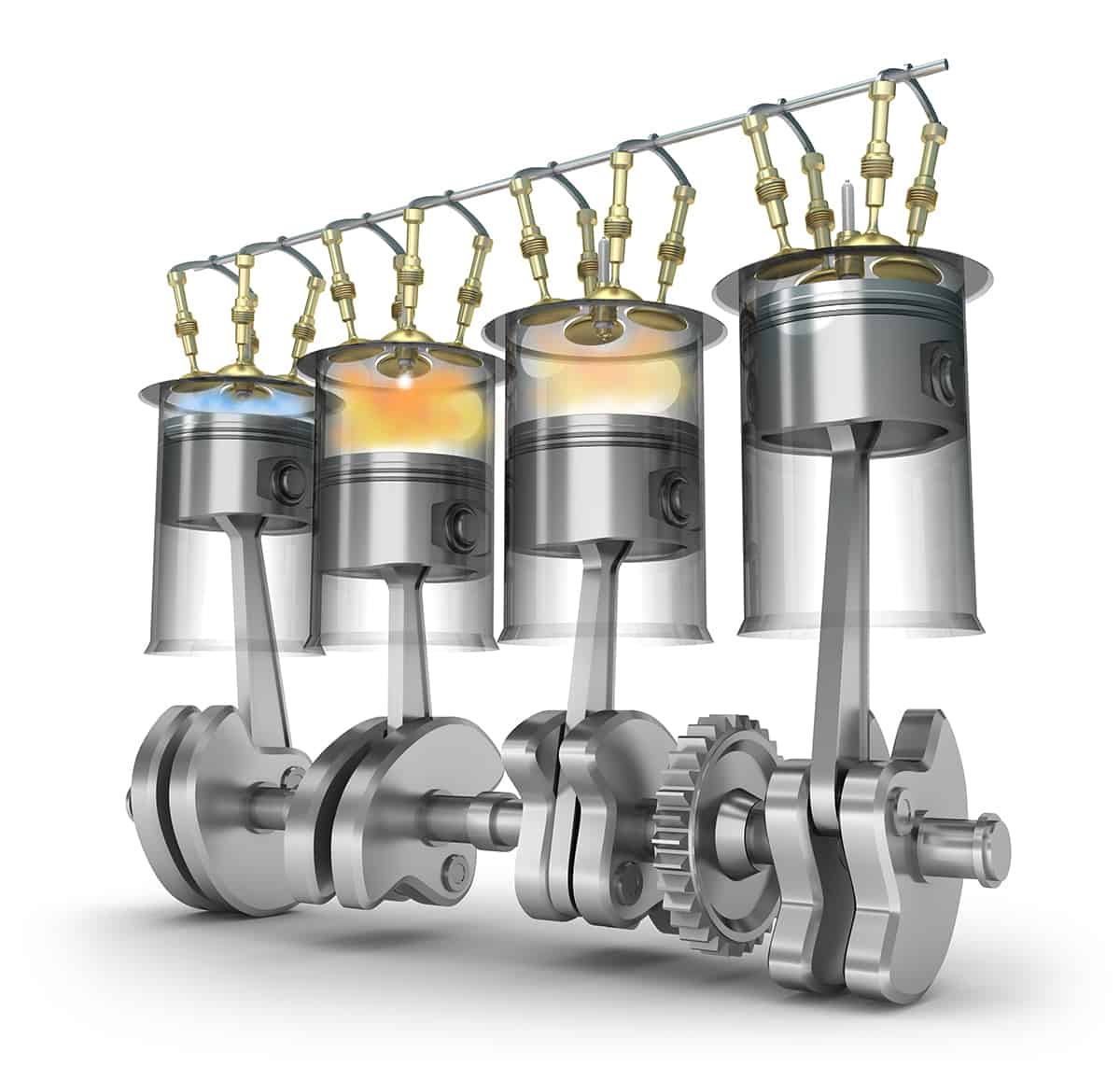

Engine compression is a measure of the pressure generated when the air-fuel mixture is squeezed together in a car’s cylinder. Ideally, an engine maintains a specific compression ratio to ensure optimal performance. This ratio refers to the difference in cylinder volume from when the piston is at the bottom of its stroke (BDC) to when it’s at the top (TDC).

As part of the four-stroke cycle—intake, compression, combustion, and exhaust—the compression stage significantly contributes to your vehicle’s power output. During this phase, the air-fuel mixture in the cylinder is compressed by the piston’s upward motion, thereby increasing the mixture’s density and potential energy.

When the spark plug ignites the compressed mixture, the energy release drives the piston downward, turning the crankshaft and ultimately propelling the car forward. High compression allows for a more substantial energy release, leading to greater engine power and better fuel efficiency.

What Is Low Engine Compression?

Low engine compression is a condition where an engine fails to achieve the necessary compression within its cylinders. Essentially, it means that the air-fuel mixture isn’t compressed enough.

For instance, if the volume changes from 10 units at BDC to 1 unit at TDC, the compression ratio is 10:1. Engines are designed to operate within specific compression ratios, and when the actual compression deviates significantly from this, problems can occur. Low engine compression is when the air-fuel mixture in the cylinders doesn’t get compressed enough.

Factors Leading to Low Engine Compression

Low engine compression typically arises from issues within the engine that prevent it from effectively sealing and compressing the air-fuel mixture in the cylinders. These issues can range from mechanical wear and tear to improper maintenance.

Mechanical Factors Causing Low Engine Compression

Impact of Piston Rings on Engine Compression

Piston rings are small, metal rings that fit into grooves on the outer edge of the pistons in an engine. They have two primary purposes: sealing the combustion chamber to maximize compression and regulating oil consumption by preventing excess oil from entering the combustion chamber.

These rings can wear out or break due to the high pressures and temperatures within the engine. When this occurs, they fail to create a proper seal in the cylinder, resulting in a loss of compression.

Role of Cylinder Heads and Valves in Maintaining Compression

Cylinder heads contain the valves and spark plugs and form the top of the combustion chamber. The valves manage the intake of air-fuel mixture and the expulsion of combustion gases.

Valves need to open and close at the right time for the engine to function properly. If the valves are worn or damaged, they may not seal correctly, leading to a loss of compression during the compression and combustion strokes. Additionally, a cracked cylinder head or blown head gasket can cause a compression leak, leading to low engine compression.

Timing Belt Problems and Their Effects on Compression

The timing belt synchronizes the rotation of the crankshaft and the camshaft so that the engine’s valves open and close at the right times during each cylinder’s intake and exhaust strokes. If the timing belt is worn, stretched, or misaligned, it can disrupt this synchronization, preventing the valves from sealing at the correct time, leading to compression loss.

Non-Mechanical Factors Affecting Engine Compression

Influence of Coolant and Oil Levels on Compression

If the coolant level is low or the system is not functioning correctly, the engine may overheat and possible lead to damage and potential compression loss. Low oil levels can lead to increased friction and excessive wear on the engine’s components, including those critical to maintaining compression.

Impact of Air-Fuel Mixture Ratio

The engine’s compression can also be affected by the ratio of air to fuel in the mixture being fed into the cylinders. If the mixture is too rich (too much fuel) or too lean (too much air), it can disrupt the combustion process, leading to suboptimal compression.

Symptoms of Low Engine Compression

You can typically identify low engine compression problems by looking for the following symptoms:

1. Rough Engine Idle

Your car’s engine should run smoothly and quietly while idling. If you notice the engine is vibrating excessively, making strange noises, or if the RPM fluctuates erratically while idling, this can indicate a problem with engine compression.

2. Loss of Power

This can manifest as sluggish acceleration, difficulty climbing hills, or an overall reduction in your car’s top speed. If your vehicle isn’t performing like it used to, low engine compression could be the culprit.

3. Difficulty Starting

Starting your vehicle involves the engine rapidly building up compression. If the engine’s compression is low, it may struggle to start, or it may not start at all.

4. Increased Fuel Consumption

A reduction in engine compression can lead to an increase in fuel consumption. As the engine struggles to generate the same power output with lower compression, it tends to burn more fuel to compensate.

5. Engine Misfires

Low engine compression can cause misfires, which occur when one of the engine’s cylinders fails to fire correctly. Misfires can cause the engine to run unevenly, and you may notice a stuttering or stumbling sensation when driving.

6. Engine Knocking Noise

An engine knocking noise is a distinct sound that can indicate a compression issue. This sound is often described as a “knocking” or “pinging” coming from the engine, particularly when accelerating or under load.

How to Fix Low Engine Compression Issues

You can remedy the issue of low engine compression by implementing one or several of the following solutions.

1. Repairing or Replacing Worn Out Piston Rings

Depending on the extent of the wear, you may need to replace or repair the piston rings. Replacement of piston rings is a labor-intensive process that generally involves disassembling a large part of the engine.

2. Fixing Valve Issues

If your valves aren’t sealing properly, you might need a valve job. This typically involves replacing or resurfacing the valves, valve seats, and possibly the valve guides. If the valve timing is the problem, this can usually be corrected by adjusting or replacing the timing belt or chain.

3. Repairing Cylinder Head Damage

Cylinder head damage, including cracks or a blown head gasket, can cause significant loss of compression. This task is complex and should only be done by a skilled mechanic to avoid further damage.

4. Addressing Piston Damage

Pistons are an integral part of the engine, and repairing or replacing them is a major task that involves engine disassembly. Such an operation should only be carried out by a professional.

5. Regular Maintenance and Checks

Beyond specific repairs, regular maintenance can go a long way in preventing low compression issues in the first place. This includes regular oil changes to minimize wear on the engine’s internal components and coolant system maintenance to avoid overheating.