Vehicles have become a near-essential part of modern life, getting us from A to B and everywhere in between. At the core of these machines lies a powerful and intricate system, the internal combustion engine. This engine, often simply referred to as an “ICE,” is a feat of engineering that has undergone constant evolution since its conception.

An internal combustion engine is a complex machine that generates power by burning fuel within its structure rather than externally. The fuel-air mixture’s combustion, initiated by a spark plug, causes a high-pressure gas expansion that pushes a piston. This mechanical motion is ultimately converted into the rotational movement of the wheels.

This article will traverse the labyrinth of internal combustion engines, detailing their components, and operation.

The Fundamentals of Internal Combustion Engines

When you turn the key or push the start button in your car, it springs to life, ready to ferry you to your destination. Ever wondered what really happens under the hood when you ignite the engine?

What is an Internal Combustion Engine?

An internal combustion engine (ICE) is a heat engine in which the combustion of a fuel-air mixture happens inside a cylinder. This combustion process generates high temperatures and pressures, causing the pistons inside the engine to move. This piston movement is transformed into a rotary motion that eventually drives the wheels of your car.

The ‘internal’ in internal combustion engine refers to the fact that the combustion process occurs inside the engine itself, as opposed to an external combustion engine where the energy source heats a working fluid outside the engine (like in a steam engine).

Evolution of Internal Combustion Engines

The internal combustion engine has a rich history, tracing back to the 19th century. The concept of harnessing the power of ignited fuel was first realized by inventors like Samuel Morey and Étienne Lenoir. However, it was the work of Nikolaus Otto and, later, Rudolf Diesel, that laid the groundwork for the types of internal combustion engines we see today.

Otto’s four-stroke engine, patented in 1876, became the foundation for the gasoline engines that dominate the automotive industry. Rudolf Diesel, on the other hand, introduced the principle of compression ignition, leading to the development of diesel engines, which offer better fuel economy and are commonly used in heavy-duty vehicles and machinery.

Over the years, internal combustion engines have seen numerous enhancements, ranging from fuel injection systems to turbochargers, significantly boosting their power and efficiency.

Types of Internal Combustion Engines

Internal combustion engines come in various types, each designed to suit a particular kind of vehicle and driving condition. Here are the main types you are likely to encounter:

1. Petrol Engines

Also known as gasoline engines, petrol engines operate on the principle of spark ignition. A spark plug ignites the fuel-air mixture, initiating the combustion process that drives the engine. Petrol engines are known for their high speed and smooth operation, making them ideal for passenger cars.

2. Diesel Engines

Diesel engines work on the principle of compression ignition. The air drawn into the cylinder is compressed to such a high pressure that it heats up. Diesel fuel is then injected into the hot, high-pressure air, causing it to ignite. Diesel engines are more fuel-efficient than petrol engines and deliver more torque, making them suitable for trucks, buses, and other heavy-duty applications.

3. Hybrid Engines

Hybrid engines integrate a conventional internal combustion engine with an electric motor, combining the benefits of both systems. They optimize fuel consumption and reduce emissions by switching between or combining the power from the ICE and the electric motor based on driving conditions.

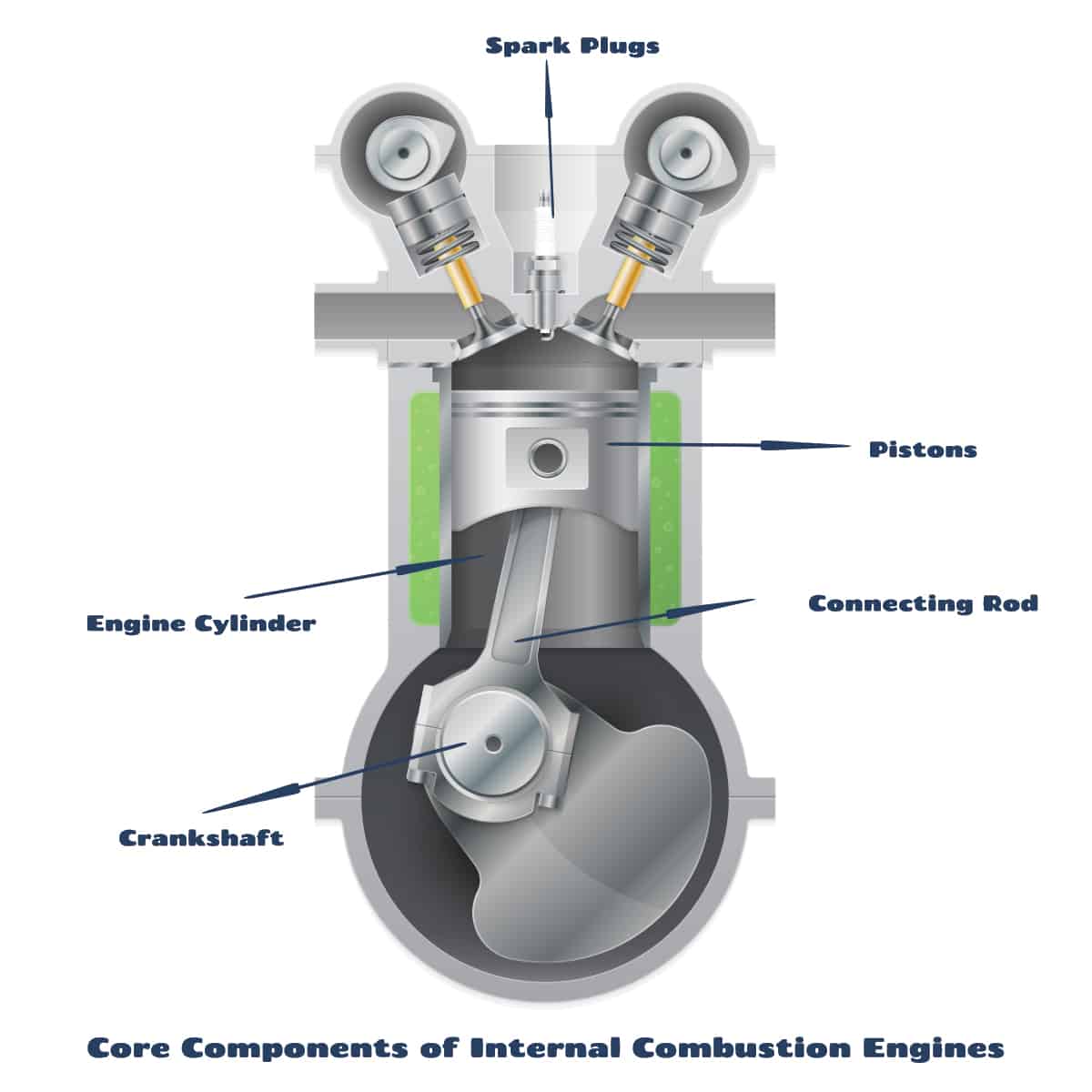

Core Components of Internal Combustion Engines

The beauty of the internal combustion engine lies in the synchronicity of its components. Every piece has a crucial role to play, and each is dependent on the others to ensure the smooth, efficient operation of the engine. In this section, we’ll dissect these parts, examining how each one contributes to transforming a simple fuel-air mixture into the mechanical energy that powers your car.

1. Engine Cylinder

Think of the engine cylinder as the heart of the internal combustion engine. It’s within these cylindrical vessels that the magic of fuel combustion takes place. The number of cylinders in an engine typically varies from one to twelve, depending on the engine’s design and the vehicle’s purpose. Most passenger cars have four, six, or eight cylinders.

Each cylinder houses a piston that moves up and down, compressing the fuel-air mixture and extracting the energy released during combustion.

2. Spark Plugs

In petrol engines, the spark plug plays a crucial role in initiating combustion. It generates a spark that ignites the compressed fuel-air mixture in the cylinder, creating a mini-explosion that pushes the piston down. The position and timing of the spark are critical for efficient engine operation.

3. Pistons

Pistons are essentially cylindrical components that move up and down within the engine’s cylinders. When the fuel-air mixture is ignited, the resulting force pushes the piston down, a process called the power stroke. The piston then returns to its original position during the exhaust stroke, expelling the combustion gasses and making room for the next cycle.

4. Connecting Rod

The connecting rod acts as a vital link between the piston and the crankshaft. Its primary role is to transfer the linear motion of the piston into the rotary motion of the crankshaft. This conversion is what ultimately drives the wheels of your vehicle.

5. Crankshaft

The crankshaft is one of the key components of the internal combustion engine. As the pistons move up and down, the connecting rods, which attach the pistons to the crankshaft, force the crankshaft to rotate. This rotation is then transferred to the vehicle’s transmission and ultimately to the wheels, propelling the vehicle forward.

Core Principles of Internal Combustion Engines

Behind the purr of your car’s engine is a complex sequence of events taking place with impressive speed and precision. The principle governing this activity is based on thermodynamics and mechanical engineering.

Four-Stroke Cycle

The four-stroke cycle, also known as the Otto cycle, is the standard operation process in most car engines. As the name suggests, it consists of four key phases: intake, compression, power, and exhaust.

1. Intake Stroke

During the intake stroke, the piston moves down in the cylinder while the intake valve opens. This action draws in a mixture of fuel and air into the cylinder.

2. Compression Stroke

As the piston moves back up the cylinder, it compresses the fuel-air mixture. Both the intake and exhaust valves remain closed during this stage. This compression makes the mixture highly explosive.

3. Power Stroke

Once the fuel-air mixture is compressed, the spark plug ignites it. The resulting explosion drives the piston down with great force, which turns the crankshaft.

4. Exhaust Stroke

After the combustion stroke, the exhaust valve opens as the piston moves upward, expelling the combustion gasses out of the cylinder. This concludes the four-stroke cycle.

Two-Stroke Cycle

The two-stroke engine operates on a cycle that combines the four strokes of the Otto cycle into just two. This makes two-stroke engines compact and lightweight, often used in applications where weight is a critical factor, such as motorcycles, jet skis, and chainsaws.

In a two-stroke engine, the intake and exhaust phases occur simultaneously as the piston reaches the bottom of the cylinder, while the compression and power phases happen concurrently as the piston ascends.

Comparing Two-Stroke and Four-Stroke Engines

While two-stroke engines have the advantage of being lighter and simpler, four-stroke engines dominate the automotive industry. This is primarily due to their fuel efficiency and lower emissions. Two-stroke engines, while powerful for their size, tend to consume more fuel and produce more emissions.