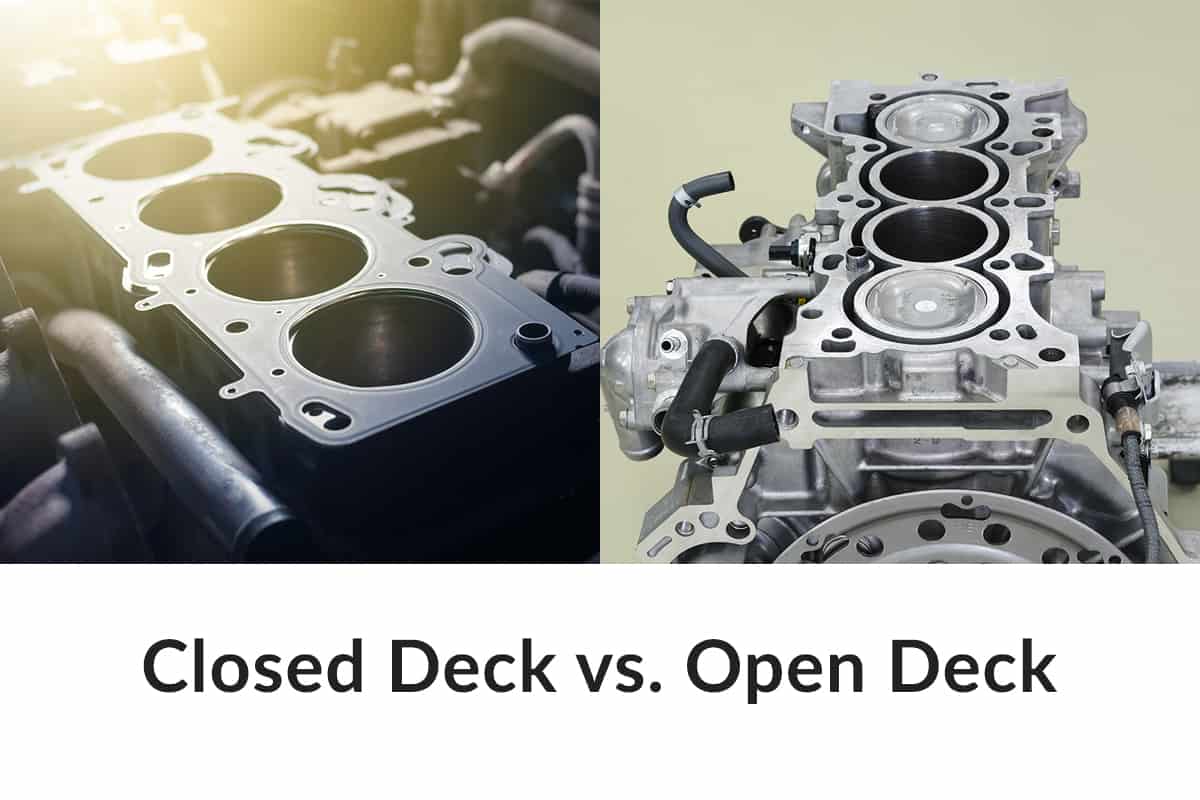

Engines form the heart of any vehicle, and their design and architecture significantly influence the vehicle’s performance. Among various design considerations, the choice between a closed deck and an open deck engine is something worth knowing. These terms refer to the arrangement of cylinders and cooling passages in an engine block, each with distinct implications for performance and durability.

In a closed deck engine, the top of the engine block around the cylinders is entirely closed except for small coolant passages, providing high rigidity and strength, ideal for high-performance applications. An open deck engine has a more substantial gap between the block and cylinders, allowing for better cooling but potentially less rigidity.

This article will cover these engine types and their advantages and disadvantages. By the end of this guide, you should have a decent idea of how they differ and which engine arrangement suits your needs better.

Open Deck Engines

Open deck engines are a common type of engine block design seen in many regular passenger vehicles. The ‘open deck’ term is derived from the significant space left open around the cylinder bores within the engine block. This area is filled with engine coolant, thus providing superior cooling capabilities compared to closed deck engines.

Advantages of Open Deck Engines

- The superior cooling capabilities help maintain optimal engine temperatures, especially crucial during long drives or in hot climates. The engine coolant can flow freely around the cylinders, dissipating heat more effectively.

- Open deck engines are typically lighter, given the reduced amount of material in the engine block. This reduction in weight can improve the vehicle’s overall fuel efficiency and handling, as less power is needed to move the vehicle.

- The production costs for open deck engines are generally lower due to the design simplicity and less material usage. This cost-effectiveness often makes these engines a more affordable option for manufacturers and consumers alike.

Drawbacks of Open Deck Engines

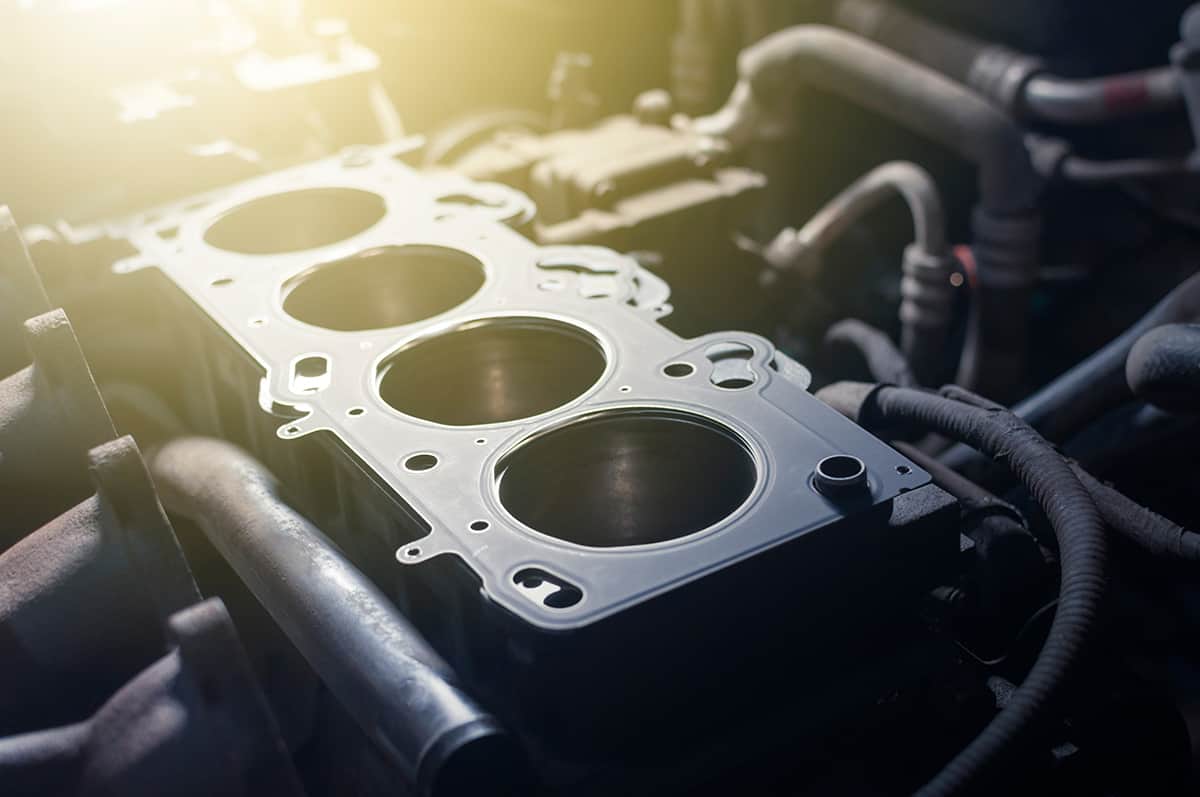

- The key concern lies in their lower structural rigidity due to the absence of additional metal support around the cylinders. Under high power demands or extreme driving conditions, the cylinders can ‘flex’ or move slightly, which may lead to a variety of issues, including head gasket failure.

- While the enhanced cooling is generally a positive aspect, it can potentially lead to uneven cooling around the cylinders. This uneven temperature distribution can cause the cylinders to warp or become out of round, particularly under high-performance demands.

Closed Deck Engines

Closed deck engines are characterized by a design where the engine block entirely encloses the cylinders, leaving only small passages for the coolant.

Essentially, this forms a ‘deck’ on top of the cylinders, hence the term ‘closed deck’. The construction significantly increases the rigidity and strength of the engine block, making it capable of withstanding higher pressures and stresses.

Advantages of Open Deck Engines

- These engines are designed to handle increased cylinder pressures that come with high-performance tuning and heavy-duty operations, making them an excellent choice for racing and performance vehicles.

- Reduced cylinder movement minimizes the risk of mechanical issues such as head gasket failure, common in open deck designs under high stress. By limiting cylinder flex, closed deck engines maintain better cylinder shape and alignment, ensuring efficient operation under demanding conditions.

Drawbacks of Closed Deck Engines

- Given the limited coolant passages around the cylinders, these engines may not dissipate heat as effectively as their open deck counterparts. This could potentially lead to overheating issues under intense operating conditions.

- Closed deck engines tend to be heavier due to the extra material in their construction. This added weight can affect vehicle handling and fuel efficiency. They’re also more expensive to produce, which could impact the vehicle’s overall cost.

Closed Deck vs. Open Deck Comparison Summary Table

| Criteria | Open Deck Engines | Closed Deck Engines |

| Performance & Durability | Suitable for regular driving conditions, not ideal for high performance | Ideal for high performance and extreme driving conditions |

| Cooling Efficiency | Superior due to greater coolant circulation around cylinders | Adequate, but may struggle under intense conditions due to limited coolant passages |

| Weight & Cost | Lighter and less expensive to produce | Heavier and more expensive due to more material usage |

Ideal Use Cases for Closed Deck and Open Deck Engines

Now that we have a basic understanding of closed-deck and open-deck engines, let’s figure out which scenarios are ideal for each type. Ultimately, the right engine type for you depends on your specific driving needs and performance requirements.

Open Deck Engines: Perfect for Daily Commuters

Open deck engines, with their superior cooling efficiency, lightweight, and cost-effective production, are excellent choices for typical daily commuting scenarios and long drives. Here’s why:

- Everyday Driving Conditions: Open deck engines offer a balance of performance, efficiency, and durability that suits regular driving conditions beautifully. They’re designed to handle the kind of use most drivers will put their cars through.

- Fuel Efficiency: Due to their lighter weight, cars with open-deck engines tend to be more fuel-efficient, making them an ideal choice for drivers looking to save on fuel costs.

- Cost-Effectiveness: Open deck engines are generally less expensive to produce and maintain, which can result in cost savings when purchasing the vehicle and during its lifecycle.

Closed Deck Engines: The Choice for Performance Enthusiasts

Closed deck engines, known for their robustness and high performance, are the go-to option for racing, high-performance driving, and heavy-duty operations. Here’s why:

- High-Performance Driving: Closed deck engines are built to handle the high cylinder pressures associated with increased power and performance. If you’re planning to tune your car for racing or high-performance driving, a closed deck engine offers the durability needed for these demanding applications.

- Racing Applications: The design of a closed deck engine minimizes cylinder movement, reducing the risk of mechanical issues like head gasket failure, a common problem in high-stress environments like racing.

- Heavy-Duty Operations: If you’re operating a vehicle under heavy-duty conditions – like towing large loads – a closed deck engine’s robustness and resilience make it a suitable choice.

FAQs

1. Can I convert an open deck to a closed deck?

Yes, it’s technically possible to convert an open deck engine into a closed deck design. This process often involves installing a closed deck insert into an open deck block, providing additional structural strength.

However, such conversions are complex and should be carried out by experienced professionals. They also require careful consideration of cooling and heat dissipation factors to avoid overheating problems.

2. What’s more suitable for high-performance tuning—open deck or closed deck?

Regarding car tuning, which refers to changing a vehicle to enhance its performance for a particular task, closed-deck engines are generally more suitable. These engines are designed to handle the high cylinder pressures associated with increased power and performance. The design minimizes cylinder movement, reducing the risk of mechanical issues like head gasket failure, a common problem in high-stress environments.

3. Are there hybrid options available in the market?

Yes, there are hybrid options known as semi-closed deck engines. The Subaru EJ25 engine is an example of a semi-closed (or semi-open) deck design.

These designs aim to combine the benefits of both open and closed deck engines. A semi-closed deck engine offers the cooling efficiency of an open deck design, along with the structural strength closer to that of a closed deck engine.

This makes them a versatile option suitable for a broader range of applications, including more intense performance demands than an open deck could handle, but without the extra weight and potential overheating concerns of a fully closed deck design.