Push rods act as the link between the camshaft and the valves. They help regulate the opening and closing of valves for both air intake and exhaust. When they’re working well, your car runs smoothly. But when a push rod bends, you’re in for a host of problems.

Signs of bent push rods include reduced engine power, strange knocking or tapping noises, and warning lights on the dashboard. If your car has bent push rods, your only option is to replace them.

This guide will cover everything you need to know about bent push rods, from identifying the issue to fixing it.

What Is a Push Rod?

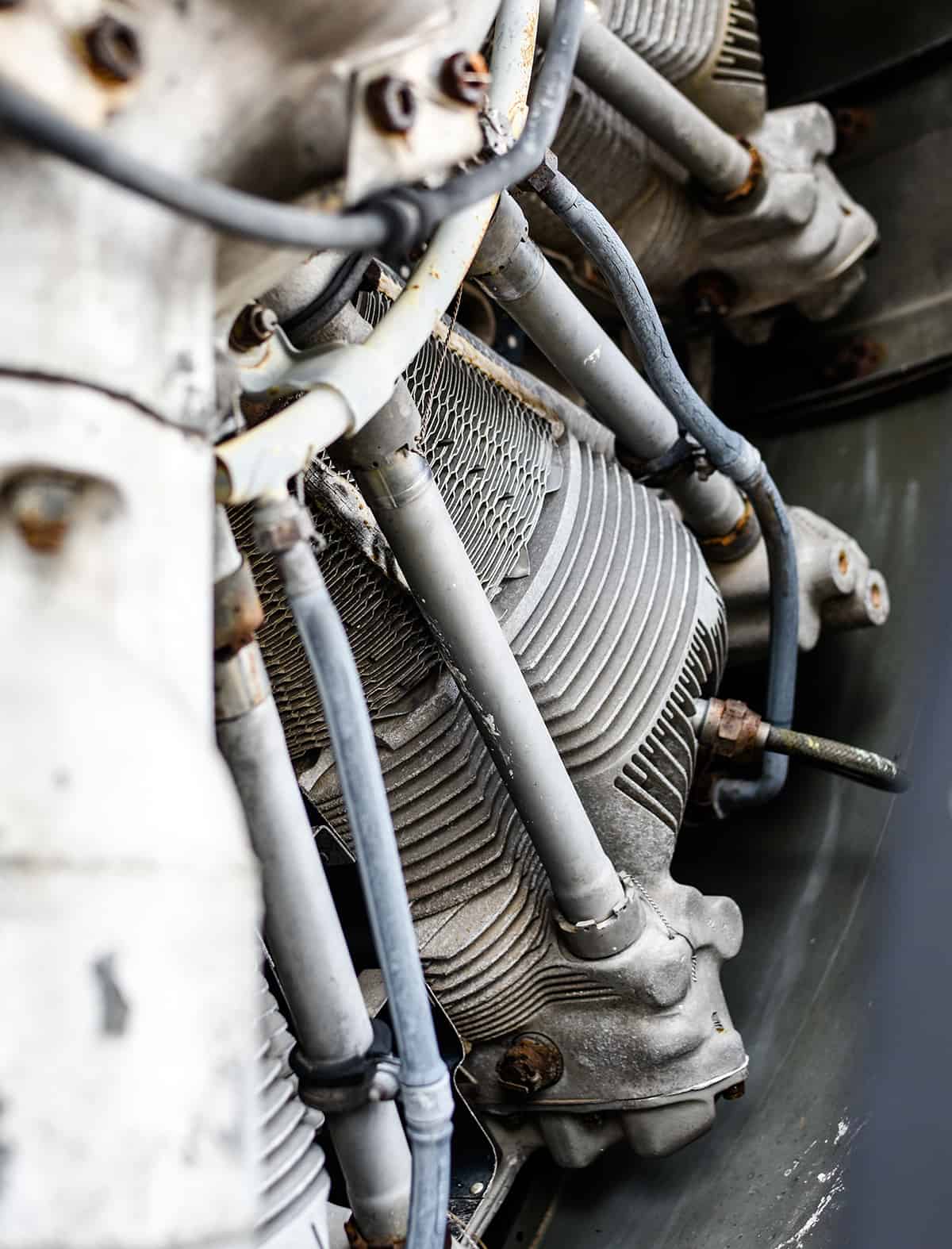

A push rod is a long, slender metal rod found in overhead valve (OHV) engines. These rods act as intermediaries between the camshaft and the engine valves. While the camshaft is responsible for determining when the valves should open or close, it’s the push rods that physically relay these instructions to the valves themselves.

Anatomy of a Push Rod

The anatomy of a push rod is relatively simple yet incredibly important. A standard push rod is a straight, cylindrical metal rod made of durable materials like steel or sometimes even titanium.

At each end of the rod, you’ll find rounded tips designed to interface smoothly with the camshaft and the rocker arms, which in turn connect to the engine valves. These rounded tips reduce friction and wear, ensuring the push rod can do its job efficiently.

Push rods are typically made from high-quality steel. Steel push rods are favored for their combination of strength and weight, allowing them to withstand the stresses and strains of the engine environment.

Some high-performance engines might use titanium push rods, as they offer exceptional durability while being lightweight. However, titanium push rods are significantly more expensive and are generally only used in specialized applications.

How Push Rods Work in an Engine

In a typical four-stroke engine cycle, the camshaft rotates and comes into contact with the bottom tip of the push rod. This pushes the rod upward and transfers this movement to the rocker arm.

The rocker arm then pivots, opening the engine valve to either let air in (intake valve) or let exhaust gases out (exhaust valve). Once the camshaft rotates away, valve springs push the push rod back down, closing the valve.

Signs Your Push Rod May Be Bent

A bent or damaged push rod can cause a variety of problems that may range from minor nuisances to severe engine issues. Here, we’ll briefly cover what those problems are.

1. Performance Issues

You may experience loss of power during acceleration or notice that your car isn’t running as smoothly as it should. This is because a bent push rod can interfere with the proper opening and closing of the engine valves, disrupting the air-fuel mixture and combustion process.

2. Unusual Noises

Specifically, you may hear a tapping, knocking, or ticking sound. These noises are produced when the bent push rod makes inconsistent or improper contact with the rocker arm or camshaft. Since the push rod’s movement assists in opening and closing the engine valves, any disruption in this process will lead to anomalous sounds.

3. Warning Lights on Dashboard

Modern cars come with an array of warning lights on the dashboard, including the “Check Engine” light. While this light can illuminate for many reasons, a bent push rod affecting engine performance could trigger it.

4. Engine Misfires

When the push rod is bent, it may not adequately transfer the camshaft’s motion to the engine valves. This disrupts the engine’s timing, leading to incomplete combustion in one or more cylinders. You’ll notice the effects of an engine misfire as a rough idle, stumbling, or sudden loss of power.

5. Increased Fuel Consumption

When the engine valves don’t open and close as they should, the engine has to work harder to produce the same amount of power, thus using more fuel.

6. Difficulty Starting the Engine

Engine starting problems can be due to many factors, but given the role of push rods in engine operation, it’s worth considering them as a potential source of the problem.

7. Exhaust Smoke

A bent push rod can cause improper valve timing, which can lead to incomplete combustion and thus more smoke exiting through the exhaust system.

How to Replace Bent Push Rods

Replacing bent push rods needs to be done with precision and care. Failure to correctly replace these engine components can lead to additional engine damage and increased repair costs.

This section will provide a general guideline on how to replace bent push rods. If you don’t possess the know-how to access and remove the push rods, you should hire a professional mechanic.

Gather Necessary Tools and Parts

These typically include a socket set, wrenches, torque wrench, screwdrivers, and of course, new push rods compatible with your engine. Make sure to consult your car’s manual for any specific tools required. Having everything at hand will streamline the replacement process, minimizing downtime and potential errors.

Safety First

Make sure the car is parked on a level surface, and the engine has cooled down. Disconnect the battery to prevent accidental electrical shorts. Wearing safety gloves and goggles is highly recommended as you’ll be dealing with various engine components that could be hot, sharp, or greasy.

1. Remove Engine Components for Access

To get to the push rods, you’ll usually need to remove some engine components, such as the air filter, intake manifold, or valve covers, depending on your specific vehicle. Use your socket set and wrenches to carefully take off these components, remembering to keep all screws and bolts organized for reassembly.

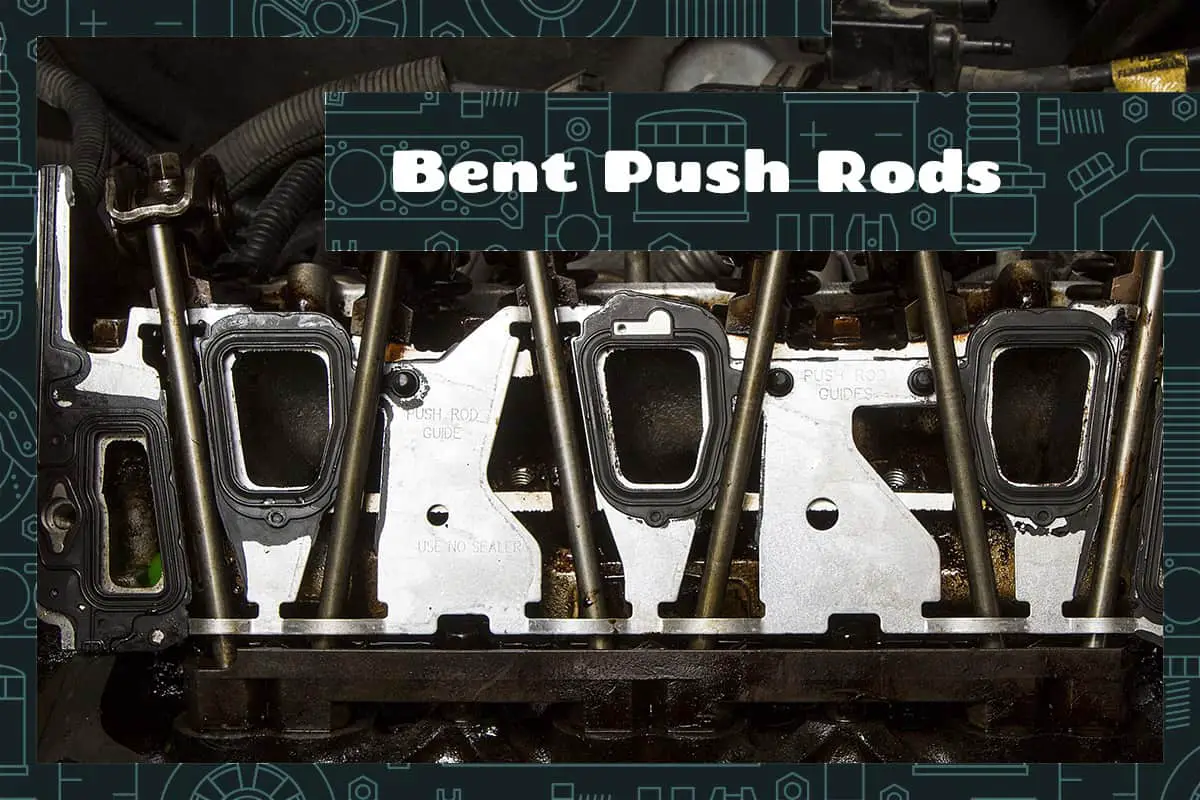

2. Locate and Assess the Bent Push Rods

With the engine components removed, you should have a clear view of the push rods. Inspect each one to identify which are bent. Bent push rods can often be visually spotted, but in some cases, you may need to remove them for a more detailed inspection. Keep track of the location of each bent push rod; this is essential for the reinstallation process.

3. Remove the Bent Push Rods

To remove the bent push rods, you’ll generally need to loosen the rocker arms that sit atop them. Once the rocker arms are loosened, carefully lift them off and set them aside. After that, you can pull out the bent push rods. Some might require a bit more effort to remove, especially if they are severely bent.

4. Prepare the New Push Rods

Before installing the new push rods, it’s a good idea to lubricate them lightly with engine oil. This helps in reducing friction during the initial startup after replacement, ensuring that the new push rods can operate smoothly.

5. Install the New Push Rods

To install the new push rods, simply reverse the removal process. Insert each new push rod into its respective slot. Make sure they are positioned correctly, sitting well within the lifter and making proper contact with the rocker arms. Re-tighten the rocker arms, adhering to the torque specifications provided in your vehicle’s manual.

6. Reassemble the Engine Components

Once the new push rods are securely in place, you can start reassembling the engine components that were removed earlier. Make sure to tighten all screws, bolts, and clamps securely, and double-check to ensure you haven’t missed anything.

7. Reconnect the Battery and Test

After everything is reassembled, reconnect the car battery. Start the engine and listen carefully for any abnormal sounds that might indicate a problem. If everything sounds normal, take the car for a test drive to ensure it’s operating correctly.