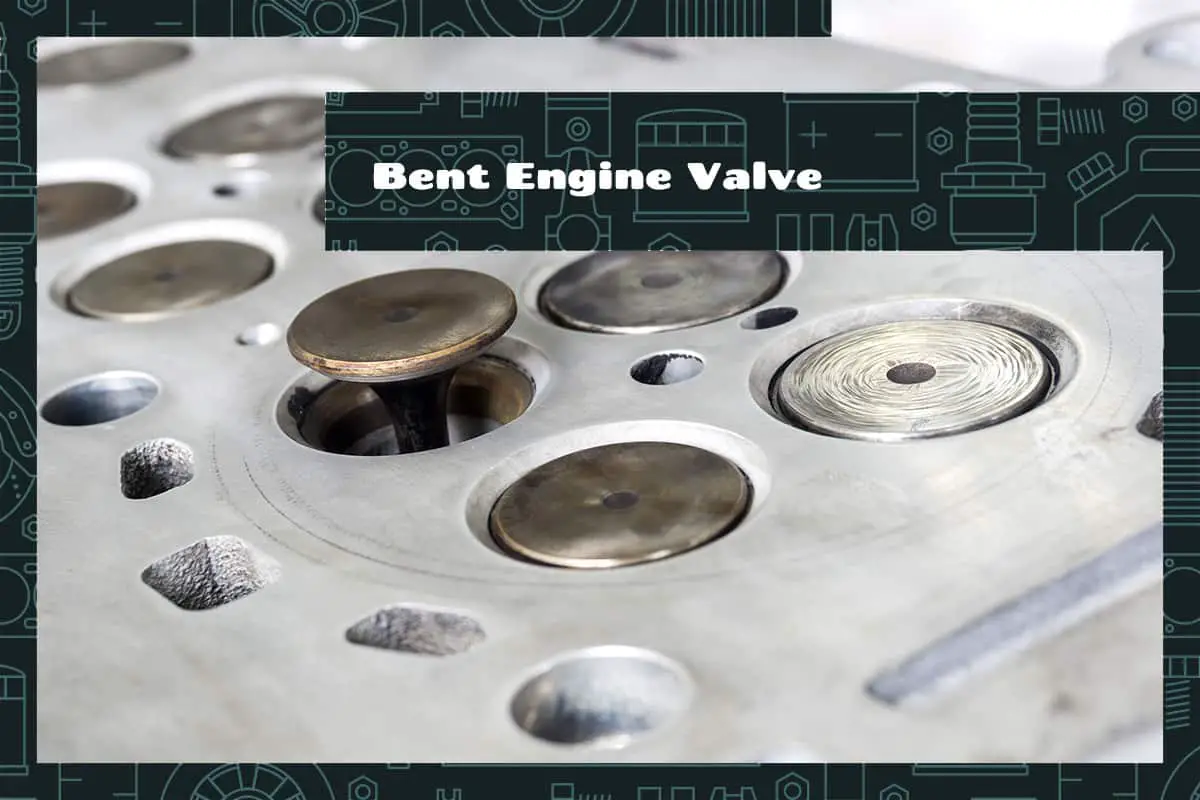

Engine valves control the intake of air and fuel and the expulsion of exhaust gasses in the combustion chamber. However, when one or more of these valves become bent, it can lead to serious performance issues.

A bent engine valve can be caused by a variety of situations, such as a timing belt failure, engine misfires, or over-revving of the engine. In any case, understanding the symptoms and learning how to address the issue promptly is important for every car owner.

The symptoms of a bent engine valve include decreased engine power, increased fuel consumption, misfires, and strange noises from the engine. To address it, you can opt for professional repair, or if you have sufficient knowledge and skill, undertake a DIY fix which includes a detailed inspection, removal, and replacement of the faulty valve.

In this guide, we will take a deeper look into the causes, symptoms, and potential consequences of bent engine valves. We will also discuss the process of diagnosing such issues and available repair options.

Introduction to Bent Engine Valves

The engine valves, typically made of steel or titanium, are situated in the cylinder head. There are two types of engine valves—intake valves, which allow the air-fuel mixture into the combustion chamber, and exhaust valves, which expel the combustion gasses. Engine valves open and close at precisely timed intervals to maintain the engine’s rhythm and efficiency.

Common Symptoms of Bent Engine Valves

Knowing the symptoms of bent engine valves can help you address the issue promptly:

Loss of Engine Power: Bent valves restrict the engine’s air-fuel flow, leading to decreased power.

- Increased Fuel Consumption: If the valve doesn’t seal properly, fuel can escape, causing increased consumption.

- Engine Misfire: Bent valves can lead to incomplete combustion, causing the engine to misfire.

- Unusual Engine Noises: You might hear a ticking or popping sound from the engine if a valve is bent.

Risks and Consequences of Ignoring Bent Engine Valves

Ignoring a bent engine valve can have severe consequences:

- Further Engine Damage: The bent valve can damage the cylinder head, piston, or the cylinder wall, leading to expensive repairs.

- Decreased Engine Lifespan: Continuous operation with a bent valve accelerates wear and tear, decreasing the engine’s lifespan.

- Safety Risks: Engine performance issues may lead to unsafe driving conditions, increasing the risk of accidents.

Bent Engine Valve Causes

Let’s examine four primary causes: timing belt failure, engine misfires, hydrostatic lock, and over-revving of the engine.

1. Timing Belt Failure

The timing belt is a vital part of an engine, controlling the synchronization between the crankshaft and the camshaft. This belt ensures that the intake and exhaust valves open and close at the right time, facilitating the smooth running of your engine.

However, if the timing belt fails or breaks, the pistons and valves can collide. Since the piston moves much faster than the valves, the impact can bend the valves, particularly the intake ones that are in the open position during the intake stroke.

Regular maintenance is essential to prevent timing belt failure. Manufacturers usually provide a recommended timing belt replacement interval, often between 60,000 to 100,000 miles. Ignoring this advice can result in a failed timing belt and consequent bent valves.

2. Engine Misfires

Engine misfires are another common cause of bent valves. An engine misfires when the air-fuel mixture in a cylinder fails to ignite properly. This can happen due to several reasons, including an improperly functioning spark plug, fuel injector, or even the Engine Control Unit (ECU).

A misfire disrupts the engine’s balance, which can create abnormal pressure situations inside the combustion chamber. This could force a valve to stay open longer than it should, increasing the risk of a piston-valve collision and, subsequently, a bent valve.

Ensuring the proper functioning of your car’s ignition and fuel delivery systems can prevent misfires and protect your engine valves.

3. Hydrostatic Lock

Hydrostatic lock, or hydrolock, occurs when a substantial amount of liquid, typically water, enters the combustion chamber in place of the air-fuel mixture. This happens most commonly when driving through deep water or flooding conditions.

Unlike gasses, liquids are nearly incompressible. When the piston moves upwards during the compression stroke, the liquid cannot be compressed and ends up forcing the valve to bend.

Avoiding deep water and ensuring your car’s air intake system is high and dry can prevent hydrolock. If you suspect water in your engine, do not attempt to start the car. Instead, have it inspected by a professional.

4. Over-revving of Engine

Over-revving refers to pushing the engine beyond its limits, often beyond the redline on the tachometer. During high revs, the valves operate at very high speed. If the engine speed exceeds the valve’s ability to close in time, a piston might strike an open valve, causing it to bend.

Most modern cars come with a rev limiter to prevent over-revving. However, manual transmission cars can still over-rev due to driver error, like a missed gear shift, often referred to as a “money shift.”

Practicing mindful and responsible driving can protect your engine from the damage caused by over-revving.

Dealing with Bent Engine Valves

If you suspect that your car has a bent engine valve, the next step is to determine the best course of action. Let’s examine the options available: seeking professional help or undertaking a DIY repair.

When to Opt for Professional Repair

If you’re not comfortable with complex mechanical tasks or lack the necessary tools, seeking professional help is the best option. Mechanics have the expertise and equipment to diagnose and repair bent engine valves.

While the cost of professional repair can be significant, remember that you’re paying for their experience and the assurance of a job done right.

Comprehensive Guide to DIY Repair

DIY repair can be a viable option if you have a good understanding of car mechanics, the correct tools, and the time to commit. Note that repairing a bent valve is a complex task that requires precision. Here’s what you need to know before attempting to repair a bent engine valve by yourself.

Tools and Materials Required

To carry out this task, you’ll need several tools and materials:

- Engine valve spring compressor

- Torque wrench

- Valve guide remover and installer

- Cylinder head overhaul kit

- Replacement valves

- Basic hand tools

Always wear safety glasses to protect your eyes and use mechanic’s gloves to guard your hands against sharp objects and chemicals.

Step-by-Step Guide to Fixing Bent Engine Valves

- Disconnect the Battery: Before starting any engine work, disconnect the battery to prevent accidental starts.

- Remove the Cylinder Head: Remove the engine components obstructing the cylinder head, including the intake manifold, exhaust manifold, and timing belt or chain. Then, unbolt and remove the cylinder head.

- Remove the Bent Valve: Using the valve spring compressor, remove the valve springs, followed by the valve itself.

- Inspect the Engine: Inspect the valve guide, seat, and the piston for any damage. If the guide is damaged, use the valve guide remover and installer to replace it.

- Install the New Valve: Apply a thin layer of engine oil to the new valve stem and guide, then insert the valve into the guide. Install the valve spring and cap using the spring compressor.

- Reassemble the Engine: After replacing all the bent valves, reassemble the engine in the reverse order of disassembly.

- Start the Engine: Once everything is in place, start the engine and listen for any unusual sounds. If the engine runs smoothly and quietly, the repair was a success.